Fiber Optic Enclosures play a vital role in protecting sensitive connections. A fiber optic box keeps each fibre optic connection secure, while a fibre optic connection box provides structured organization. Unlike a fiber optic box outdoor, a fiber optic cable box designed for indoor use ensures optimal performance in controlled environments.

Key Takeaways

- Keep fiber optic cables organized inside enclosures by planning cable paths, using clips and trays, and labeling cables clearly to prevent tangling and signal loss.

- Always clean and terminate fiber connectors properly using the right tools and methods to avoid contamination and ensure strong, reliable network signals.

- Respect the minimum bend radius for fiber cables by avoiding sharp bends and using guides to protect cables from damage and maintain network performance.

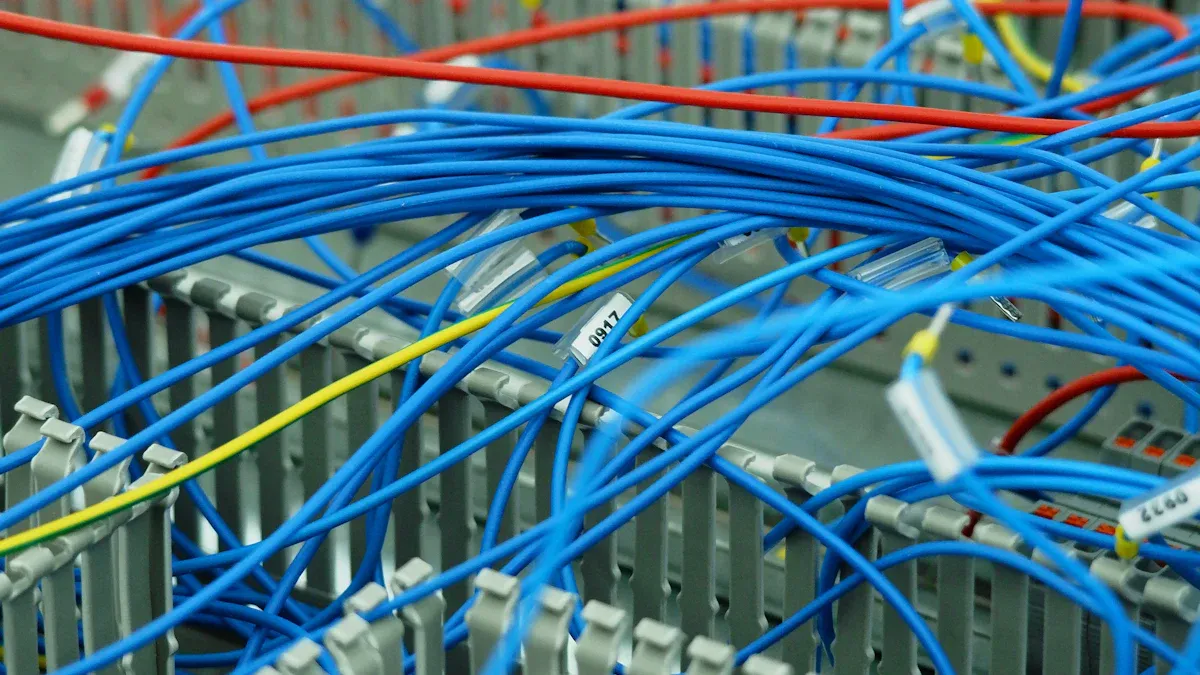

Poor Cable Management in Fiber Optic Enclosures

What Poor Cable Management Is and Why It Happens

Poor cable management occurs when fiber optic cables inside enclosures become tangled, overcrowded, or improperly routed. This situation often results from rushed installations, lack of planning, or insufficient training. Technicians may overlook the importance of using cable trays, racks, or clips, leading to cables crossing over each other or sagging. When cables are not labeled or separated, troubleshooting becomes difficult and time-consuming. Over time, tangled cables can cause signal loss, physical damage, and even overheating due to restricted airflow. In high-density environments, such as data centers, poor organization inside Fiber Optic Enclosures can compromise network reliability and increase maintenance costs.

How to Avoid Poor Cable Management

Technicians can prevent cable chaos by following industry standards and best practices. Careful planning of cable paths and lengths ensures cables reach their destinations without excess slack. Using cable management accessories, such as trays, racks, and high-quality cable clips like those from Dowell, keeps cables secure and prevents tangling. Proper spacing of clips—every 12 to 18 inches horizontally and every 6 to 12 inches vertically—maintains cable integrity. Technicians should avoid over-tightening clips to protect the cable jacket. Clear labeling at both ends of each cable simplifies maintenance and troubleshooting. Regular audits and visual inspections help maintain organization and compliance. Training programs, such as the CNCI® Fiber Optic Cabling course or BICSI certifications, equip technicians with the skills needed for effective cable management. These steps ensure Fiber Optic Enclosures remain organized, support efficient airflow, and provide a reliable foundation for network performance.

Improper Fiber Termination in Fiber Optic Enclosures

What Improper Fiber Termination Is and Why It Happens

Improper fiber termination occurs when technicians fail to prepare, align, or finish fiber ends correctly inside Fiber Optic Enclosures. This mistake often results from rushed work, lack of training, or using the wrong tools. Common errors include contamination by dust or oils, scratches on the fiber end face, and poor connector alignment. These issues cause high insertion loss, signal reflections, and even permanent damage to connectors. In some cases, improper cleaning during termination can lead to failure rates as high as 50% or more. Each faulty connection point introduces measurable insertion loss, which can exceed the loss within the fiber cable itself. As a result, network speed and reliability suffer, especially in high-speed environments. Dowell emphasizes the importance of proper termination to prevent these costly problems and ensure stable network performance.

How to Ensure Proper Fiber Termination

Technicians can achieve reliable terminations by following industry standards and using the right tools. The process starts with careful cleaning using lint-free wipes and approved solvents. Operators should avoid reusing wipes or over-wetting fibers, as these habits spread contaminants. Proper connector termination may involve splicing pigtails, using fanout kits, or applying adhesives like epoxy. Crimping tools must match the connector type and apply the correct force. Dowell recommends regular inspection and testing of each termination to catch defects early. Technicians should polish connectors in three steps and avoid overpolishing, which can undercut the fiber surface. Pre-terminated cables and rugged connectors simplify installation and reduce field errors. By documenting all terminations and maintaining a dust-free environment, teams can minimize insertion loss and maximize network reliability.

Ignoring Bend Radius Guidelines in Fiber Optic Enclosures

What Ignoring Bend Radius Means and Why It Happens

Ignoring bend radius guidelines means technicians bend fiber optic cables tighter than recommended inside Fiber Optic Enclosures. This mistake often happens when installers try to fit too many cables into a small space or rush to finish a job. Sometimes, they may not know the correct minimum bend radius for each cable type. When a cable bends too sharply, light signals can leak from the fiber. This leakage increases insertion loss and weakens the signal. Over time, sharp bends can create micro cracks in the glass, which may not be visible but will degrade performance. In severe cases, the fiber can break completely. Even if the damage is not obvious at first, network reliability drops and data integrity suffers.

How to Maintain Correct Bend Radius

Technicians can protect fiber optic cables by following industry guidelines for bend radius. Most single-mode fibers require a minimum bend radius of about 20 mm, while multimode fibers need around 30 mm. The general rule is to keep the bend radius at least 10 times the cable diameter. If the cable is under tension, increase the bend radius to 20 times the diameter. For example, a cable with a 0.12-inch diameter should not bend tighter than 1.2 inches. Some advanced fibers, like Bend Insensitive Single Mode Fiber (BISMF), allow for smaller bend radii, but installers should always check manufacturer specifications. Dowell recommends using cable management accessories, such as radius guides and cable trays, to prevent accidental sharp bends. Technicians should avoid forcing cables into tight corners or overcrowding enclosures. Regular inspections help catch problems early. By respecting bend radius guidelines, teams ensure Fiber Optic Enclosures deliver reliable performance and long-term durability.

Inadequate Cleaning of Fiber Connectors in Fiber Optic Enclosures

What Inadequate Cleaning Is and Why It Happens

Inadequate cleaning of fiber connectors occurs when technicians fail to remove dust, dirt, or oils from connector end-faces before installation or maintenance. Even microscopic particles can block the fiber core, causing signal loss and back reflections. In one documented case, contamination from a dirty OTDR jumper led to a 3 to 6 dB drop in signal-to-noise ratio across 3,000 terminations. This level of degradation can destabilize laser systems and disrupt network performance. Common contaminants include fingerprints, lint, human skin cells, and environmental dust. These substances often transfer during handling, from dust caps, or through cross-contamination when connectors mate. Dirty connectors not only reduce signal quality but can also cause permanent damage to mating surfaces, resulting in high attenuation and costly repairs. Regular and proper cleaning remains critical for maintaining the performance of Fiber Optic Enclosures.

How to Properly Clean Fiber Connectors

Technicians should follow a systematic approach to cleaning fiber connectors. Inspection with a microscope comes first to identify visible debris. For light contamination, dry cleaning with lint-free wipes or a reel cleaner works well. If oily or stubborn residues persist, wet cleaning with a specialized solvent—not standard isopropyl alcohol—should be used. After each cleaning step, technicians must inspect the connector again to ensure all contaminants are gone. Dowell recommends using professional cleaning tools such as fiber optic cleaning pens, cassettes, and cleaning boxes. These tools help prevent static buildup and secondary contamination. Technicians should avoid cotton swabs, paper towels, and compressed air, as these can introduce new contaminants or leave fibers behind. Always keep dust caps on when connectors are not in use. Cleaning both connectors before mating prevents cross-contamination and maintains optimal signal quality. Consistent inspection and cleaning routines protect the integrity of fiber networks and extend the lifespan of Fiber Optic Enclosures.

Skipping Regular Maintenance of Fiber Optic Enclosures

What Skipping Maintenance Is and Why It Happens

Skipping regular maintenance means neglecting routine inspections, cleaning, and testing of Fiber Optic Enclosures. Many teams overlook these tasks due to time constraints, lack of training, or the assumption that enclosures are maintenance-free. Over time, dust, moisture, and physical stress can build up inside the enclosure. This leads to connector contamination, signal loss, and even premature equipment failure. Technicians sometimes forget to check for damaged seals or worn gaskets, which allows moisture to enter and corrode internal components. Without scheduled maintenance, small issues go unnoticed until they cause network outages or expensive repairs.

Note: Neglecting regular maintenance often results in hidden problems that escalate quickly, increasing downtime and costs.

How to Implement Effective Maintenance

A structured maintenance plan keeps Fiber Optic Enclosures operating at peak performance. Dowell recommends the following best practices:

- Conduct regular inspections to spot damage, dirt, or wear early. Check seals, gaskets, and the physical condition of the enclosure.

- Clean connectors and splice trays using approved tools, such as lint-free wipes and specialized solvents, to prevent signal loss.

- Monitor temperature and humidity inside the enclosure to avoid moisture buildup and overheating.

- Replace damaged parts, such as cracked seals or worn gaskets, as soon as possible.

- Test fiber optic links periodically to verify signal quality and detect any degradation.

- Maintain detailed documentation of inspections, test results, and repairs for future reference.

- Train maintenance personnel to follow industry standards and use proper cleaning and testing methods.

By following these steps, teams can extend the lifespan of their enclosures and reduce the risk of unexpected failures.

Quick Reference Table for Fiber Optic Enclosures

Summary of Common Mistakes and Solutions

A quick reference table helps technicians and network managers evaluate Fiber Optic Enclosures efficiently. The following tables summarize essential metrics and provide actionable solutions for common mistakes.

Tip: Use these tables as a checklist during installation and maintenance to ensure reliable performance.

Key Metrics for Fiber Optic Enclosure Performance

| Metric | Description | Typical Values / Notes |

|---|---|---|

| Core Diameter | Central region for light transmission; impacts bandwidth and distance | Single-mode: ~9 μm; Multimode: 50 μm or 62.5 μm |

| Cladding Diameter | Surrounds core, ensures internal reflection | Typically 125 μm |

| Coating Diameter | Protective layer over cladding | Usually 250 μm; tight-buffered: 900 μm |

| Buffer/Jacket Size | Outer layers for durability and handling | Buffer: 900 μm–3 mm; Jacket: 1.6–3.0 mm |

| Fiber Type | Determines application and performance | Single-mode (long distance); Multimode (short distance, higher bandwidth) |

| Bend Radius Sensitivity | Indicates risk of signal loss from tight bends | Follow manufacturer guidelines |

| Cleaning & Inspection | Maintains signal integrity | Use high-precision tools and inspection equipment |

| Connector Compatibility | Ensures proper mating and minimal loss | Match connector type and polish |

| Industry Standards | Guarantees compatibility and reliability | ITU-T G.652, ISO/IEC 11801, TIA/EIA-568 |

| Color Coding & Identification | Simplifies management and reduces errors | Yellow: single-mode; Orange: OM1/OM2; Aqua: OM3/OM4; Lime Green: OM5 |

Common Mistakes and Effective Solutions

| Common Mistake | Effective Solution |

|---|---|

| Not Cleaning Fiber Connectors Properly | Use lint-free wipes and optical-grade solutions; inspect after cleaning; provide regular training |

| Improper Fiber Splicing | Follow precise splicing steps; use quality tools; test with OTDR or power meter; ensure technician training |

| Bending Fiber Optic Cables Too Tightly | Adhere to bend radius specifications; use bend radius guides; plan routing carefully |

| Incorrect Fiber Termination | Prepare fiber before termination; use correct connectors; polish end faces; test after termination |

| Neglecting Proper Cable Management | Label and route cables properly; secure with ties and guides; avoid overstuffing; maintain organization |

These tables support best practices for Fiber Optic Enclosures and help teams avoid costly errors.

Avoiding common mistakes with Fiber Optic Enclosures improves network reliability and reduces costly downtime. Proper management and maintenance lower replacement frequency and labor costs. Industry studies show that clean connectors and organized cables prevent outages. For best results, teams should follow recommended practices and consult trusted resources for ongoing support.

FAQ

What is the recommended frequency for inspecting indoor fiber optic enclosures?

Technicians should inspect enclosures every three to six months. Regular checks help prevent dust buildup, connector contamination, and physical damage.

Can technicians use standard alcohol wipes for cleaning fiber connectors?

Specialized optical-grade solvents work best. Standard alcohol wipes may leave residue or fibers, which can degrade signal quality.

How does proper labeling improve fiber optic enclosure maintenance?

Clear labeling allows technicians to identify cables quickly. This practice reduces troubleshooting time and prevents accidental disconnections.

By: Eric

Tel: +86 574 27877377

Mb: +86 13857874858

E-mail: henry@cn-ftth.com

Youtube: DOWELL

Pinterest: DOWELL

Facebook: DOWELL

Linkedin: DOWELL

Post time: Jul-24-2025