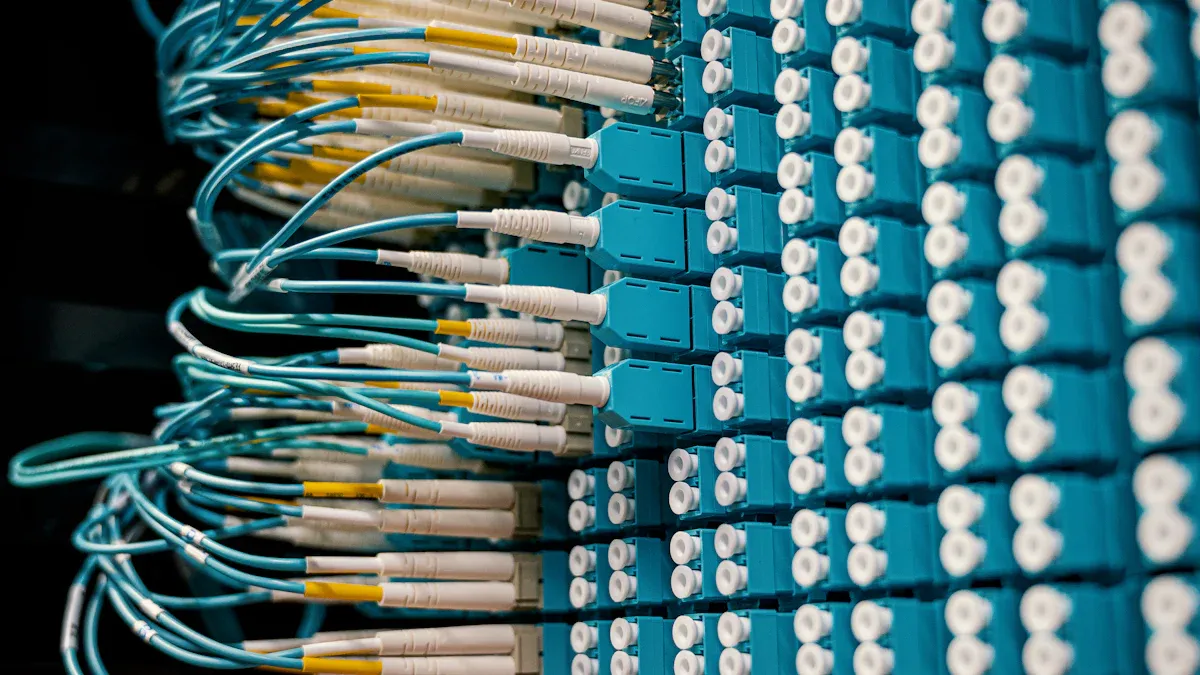

Fiber optic cables are essential for reliable communication in the oil and gas industry. They provide unparalleled bandwidth, immunity to electromagnetic interference, and transmit data over long distances in harsh environments. This directly addresses the critical need for robust data transfer. Communication problems can lead to significant financial losses, potentially costing tens of thousands per employee annually.

Key Takeaways

- Fiber optic cables are very important for oil and gas. They send data fast and work well in tough places.

- These cables help keep workers safe. They also make sure oil and gas operations run smoothly.

- Fiber optics help find oil and gas. They also check pipelines and control machines from far away.

Unique Communication Challenges in Oil & Gas Operations

Harsh Operating Environments for Fiber Optic Cable

Oil and gas operations occur in some of the planet’s most challenging environments. Equipment, including communication infrastructure, must endure extreme conditions. Fiber optic cables, for instance, often operate in temperatures ranging from -40°C to +85°C. Specialty cables can even withstand temperatures up to 500°C, with some optical fibers tolerating up to 1000°C. These cables also face immense pressure, designed to endure hyperbaric conditions up to 5000 bar. Such resilience is crucial for reliable data transfer in deserts, arctic regions, and deep-sea installations. Dowell provides solutions for these demanding environments.

Remote and Distributed Operations Demanding Fiber Optic Cable

Oil and gas facilities are frequently located in remote, isolated areas, far from urban centers. Pipelines, for example, often stretch thousands of miles across multiple states or countries. This vast geographical spread necessitates robust long-range communication solutions. Experts often need to communicate with field staff hundreds of miles away, or even in different parts of the world. Offshore platforms and rigs also require reliable connections, often relying on satellite communication for their global availability. This distributed nature makes communication a complex challenge.

Criticality of Real-time Data Transmission via Fiber Optic Cable

Real-time data transmission is paramount for safety and efficiency in oil and gas operations. Control systems monitor critical processes, requiring immediate feedback. An experimental pressure monitoring system, for example, achieved an average latency of 150 ms, meeting industrial real-time communication needs. Modern safety-critical systems often demand even faster responses, sometimes requiring sub-millisecond latency. This rapid data flow enables quick decision-making and prevents potential hazards. The reliability of Fiber Optic Cable ensures this critical data moves without interruption.

Key Advantages of Fiber Optic Cables for Oil & Gas Communication

High Bandwidth and Data Capacity of Fiber Optic Cable

The oil and gas industry generates vast amounts of data, from seismic surveys to real-time well monitoring. This demands communication infrastructure capable of handling immense data volumes at high speeds. Fiber optic cables excel in this regard, offering significantly higher bandwidth and data capacity compared to traditional copper cables. They routinely support speeds of 10 Gbps, 40 Gbps, and 100 Gbps, with capabilities scaling towards 400 Gbps and beyond. Future capacities could reach terabits per second (Tbps).

| Feature | Fiber Optic Cables | Copper Cables |

|---|---|---|

| Data Transmission Speed | Up to 800 Gbps (future: 1.6 Tbps) | Up to 10 Gbps (limited distance) |

| Typical Speeds | 10 Gbps, 40 Gbps, 100 Gbps, 400 Gbps, Tbps | 10 Gbps (Cat 6A over 100m), 25–40 Gbps (Cat 8 over ≤30m) |

This superior capacity ensures efficient data transfer for complex operations, enabling faster analysis and decision-making.

Immunity to Electromagnetic Interference (EMI) with Fiber Optic Cable

Oil and gas environments are rife with sources of electromagnetic interference (EMI), such as powerful motors, generators, and high-voltage power lines. These can severely disrupt electrical signals carried by copper cables, leading to data corruption and communication failures. Fiber optic cables, however, are immune to EMI. They consist of dielectric materials and operate passively, meaning they do not require electrical power at the sensing location. This inherent design prevents signal degradation from:

- Low-frequency pulse interference (LPI)

- Power line interference (PLI)

Their electrical isolation and lack of electrical power requirements at the sensor head also reduce the risk of failure when exposed to conductive liquids like water or reservoir fluids. This immunity ensures stable and reliable communication in electrically noisy environments.

Long-Distance Transmission with Minimal Loss using Fiber Optic Cable

Oil and gas operations often span vast distances, from extensive pipeline networks to remote offshore platforms. Transmitting data reliably over these long stretches presents a significant challenge for traditional communication methods. Fiber optic cables transmit light signals with minimal attenuation, allowing them to cover much greater distances without the need for frequent signal boosting. This capability reduces infrastructure complexity and maintenance costs, making them ideal for connecting widely dispersed assets and control centers.

Enhanced Safety and Security with Fiber Optic Cable

Safety is paramount in the oil and gas industry, especially in environments with flammable gases and liquids. Fiber optic cables do not carry electrical currents, eliminating the risk of sparks or electrical shorts that could ignite explosive atmospheres. This makes them inherently safer for deployment in hazardous areas. Furthermore, fiber optic communication offers enhanced security. Tapping into a fiber optic line without detection is extremely difficult, providing a secure channel for sensitive operational data and preventing unauthorized access.

Durability and Longevity of Fiber Optic Cable

The harsh conditions of oil and gas environments demand exceptionally durable equipment. Fiber optic cables are engineered to withstand extreme temperatures, high pressures, and corrosive substances found in subsea and downhole applications. Long-distance submarine cables, for instance, have a design life exceeding 25 years. Undersea systems, including cables, are designed to operate successfully for a minimum of 25 years under extreme environmental conditions. While the engineered lifespan is robust, an analysis of repeatered cables retired since 2010 indicates an average economic lifespan of 17 years. Companies like Dowell contribute to this critical infrastructure by providing robust and long-lasting fiber optic solutions tailored for these demanding conditions. Their resilience ensures consistent performance and reduces the need for frequent replacements, contributing to operational continuity and cost savings.

Applications of Fiber Optic Cables in Oil & Gas

Downhole Monitoring and Sensing with Fiber Optic Cable

Fiber optic cables play a crucial role in downhole monitoring and sensing, providing real-time data from deep within oil and gas wells. These sensors offer unparalleled accuracy and reliability in extreme conditions. Engineers use various types of fiber optic sensors to monitor critical parameters like temperature and pressure.

Common types of fiber optic sensors include:

- Raman scattering (used in DTS): This method is sensitive to temperature-induced phonon interactions. It is commonly used for Distributed Temperature Sensing (DTS).

- Brillouin scattering (used in DSS and DTS): This technique responds to both strain and temperature through frequency shift analysis. It finds use in Distributed Strain Sensing (DSS) and Distributed Temperature Sensing (DTS).

Specific pressure sensors also leverage fiber optics:

- FBG Pressure Sensor: These sensors are compact, immune to electromagnetic interference, and safe. They offer distributed sensing capabilities. FBG sensors have measured high temperatures and pressures (up to 400 °C and 100 MPa). They operate stably in downhole environments (e.g., 0-150 °C and 0-80 MPa) with high pressure sensitivity, meeting precision requirements for downhole exploitation.

- LPFG Pressure Sensor: Long-Period Fiber Grating sensors function through periodic refractive index modulation. This enables co-directional coupling of light. Their resonant wavelengths are highly sensitive to changes in temperature and the external refractive index, making them suitable for pressure sensing.

The table below summarizes key fiber optic sensor types and their applications:

| Sensor Type | Sensing Principle | Key Features / Application |

|---|---|---|

| Brillouin Scattering | Frequency shift of scattered light | Long-range distributed temperature sensing (up to 100 km); Measures both temperature & strain (e.g., railways, pipelines) |

| Raman Scattering (DTS) | Intensity ratio between Stokes and anti-Stokes light | Utilized in Distributed Temperature Sensing (DTS) systems; Long-distance distributed sensing (e.g., oil wells, cable tunnels) |

| Fiber Bragg Grating (FBG) | Wavelength shift in reflected light | High-precision point or quasi-distributed sensing; Fast response, high accuracy (e.g., transformers, motors, structural health monitoring) |

Seismic Exploration and Data Acquisition using Fiber Optic Cable

Seismic exploration relies heavily on accurate data acquisition to map subsurface geological structures. Fiber optic cables enhance this process significantly. They transmit vast amounts of seismic data from arrays of sensors to processing units with high fidelity and speed. Traditional geophones often suffer from electromagnetic interference and signal degradation over long distances. Fiber optic sensors, however, provide clear, interference-free signals. This allows geophysicists to create more precise images of underground reservoirs, leading to more efficient drilling and production strategies. The robust nature of these cables also ensures reliable operation in challenging field conditions.

Platform and Rig Communication Networks with Fiber Optic Cable

Offshore oil and gas platforms and rigs require robust and reliable communication networks. These networks connect personnel, control systems, and data centers. Fiber optic cables form the backbone of these critical communication infrastructures.

Common network architectures implemented on platforms include:

- Three-tier architecture: This design includes core, distribution, and access layers. It organizes the network efficiently. The core layer handles high-speed data, the distribution layer manages traffic, and the access layer connects end devices.

- Fiber optic backbone: This utilizes fiber optic cables for enhanced data transmission speed and reliability. It offers resistance to electromagnetic interference and high bandwidth.

- Wireless connectivity: This incorporates technologies like Wi-Fi and satellite connections. It provides flexibility and mobility for personnel on the platform.

- Edge computing: This reduces the need for sending all data to onshore data centers. It improves data processing efficiency and reduces latency for time-sensitive applications.

Furthermore, advanced connectivity solutions enhance offshore operations:

- Superfast subsea fiber optic network: This provides high-capacity broadband access. It enables faster decision-making, increased efficiency, improved safety, and reduced operational costs. It offers virtually no delay compared to traditional satellite communication.

- Offshore 4G LTE network: This extends network reach to mobile and rotating rigs and vessels. It offers reliable communication links even in challenging weather conditions. This addresses the limitations of high latency and limited bandwidth in satellite options.

- Point-to-point radio link connectivity: This proven technology is effective where fiber cabling is complex or costly. It offers high capacity, low latency, and high reliability. Operators commonly use it to connect fixed offshore platforms.

Pipeline Monitoring and Leak Detection via Fiber Optic Cable

Pipelines transport oil and gas across vast distances, making continuous monitoring essential for safety and environmental protection. Fiber optic cables offer an advanced solution for pipeline monitoring and leak detection. Distributed Acoustic Sensing (DAS) systems, utilizing fiber optics, detect minute vibrations along the pipeline. These vibrations can indicate leaks, intrusions, or other anomalies.

Fiber optic distributed acoustic sensing (DAS) systems detect weak leak-induced pipeline vibrations. In experiments, the smallest successfully detected leak (1 mm at 5 bars) corresponded to a leak rate of approximately 0.14% of the volume flow. Most common leak detection systems typically cannot achieve this value. This approach detects and localizes gas pipeline leaks with rates well below 1% of the pipeline flow volume.

DAS systems demonstrate high accuracy in identifying pipeline events:

| Metric | Value |

|---|---|

| Classification Accuracy | 99.04% |

| Recall Rate | 98.09% |

| F1 Score | 99.03% |

This high level of precision allows operators to quickly identify and address potential issues, preventing significant environmental damage and economic losses.

Remote Operations and Control Centers Powered by Fiber Optic Cable

The oil and gas industry increasingly relies on remote operations and centralized control centers. These facilities manage widespread assets from a single location. Fiber optic cables are indispensable for connecting these remote sites to control centers. They provide the high-bandwidth, low-latency communication necessary for real-time data exchange and remote control of equipment. This enables operators to monitor production, adjust parameters, and respond to incidents from hundreds or thousands of miles away. The reliability and speed of fiber optic networks support the digital transformation of the industry, enhancing operational efficiency, reducing on-site personnel requirements, and improving overall safety.

Challenges and Future Outlook for Fiber Optic Cables

Installation and Maintenance Considerations for Fiber Optic Cable

Deploying fiber optic cables in the oil and gas industry presents unique challenges. Installation often occurs in remote, harsh environments, requiring specialized equipment and highly trained personnel. Subsea installations, for example, demand precise laying techniques and robust protection against marine elements. Maintaining these complex networks also requires regular inspections and prompt repairs to ensure continuous operation. Companies must plan for these logistical complexities to maximize system uptime.

Cost-Benefit Analysis of Fiber Optic Cable Deployment

The initial investment for fiber optic cable infrastructure can be substantial. This includes costs for specialized cables, installation, and integration with existing systems. However, the long-term benefits often outweigh these upfront expenses. Fiber optic systems offer superior reliability, higher data capacity, and lower operational costs compared to traditional copper solutions. Their extended lifespan and reduced maintenance needs contribute to significant savings over time. This makes them a cost-effective choice for critical oil and gas operations.

Emerging Technologies and Trends in Fiber Optic Cable Use

The future of fiber optics in oil and gas involves continuous innovation in materials and sensing capabilities. Manufacturers develop advanced materials like armored, fire-resistant, and UV-protected fibers to meet rigorous standards for harsh environments. Carbon coating technology improves performance through a robust carbon layer. This layer acts as a barrier against hydrogen diffusion, ensuring functionality under high temperatures. Specialty Fiber Optic Cable designs feature high glass transition temperatures and NASA low outgassing approval. These cables suit high-temperature applications like industrial furnaces and aerospace systems. They also show exceptional durability in corrosive environments such as chemical plants and offshore oil rigs. Dowell contributes to these advancements, providing solutions for extreme conditions. Emerging trends include the development of ruggedized and high-temperature resistant cables. They also include the integration of fiber optic sensors for monitoring and control in extreme conditions.

Fiber optic cables are indispensable for reliable, high-performance communication in the oil and gas industry. They drive operational efficiency, enhance safety, and support digital transformation. These cables effectively overcome unique environmental and operational challenges. Companies like Dowell (https://www.fiberopticcn.com/about-us/) provide critical infrastructure, contributing significantly to this vital sector.

FAQ

What makes fiber optic cables ideal for oil and gas operations?

Fiber optic cables offer high bandwidth, immunity to electromagnetic interference, and long-distance data transmission. They also provide enhanced safety and durability in harsh environments.

How do fiber optic cables assist in pipeline monitoring?

Fiber optic cables, through Distributed Acoustic Sensing (DAS), detect minute vibrations along pipelines. This identifies leaks, intrusions, and other anomalies with high accuracy.

Can fiber optic cables withstand extreme temperatures in downhole applications?

Yes, specialized fiber optic cables and sensors tolerate temperatures up to 500°C, with some optical fibers enduring up to 1000°C. This ensures reliable downhole monitoring.

Post time: Dec-12-2025