A flat fiber optic drop wire clamp holds flat fiber cables in place during fiber drop cable installation. This device keeps cables secure and prevents them from slipping or getting damaged. Unlike a round optical fiber drop cable clamp, the flat fiber optic drop wire clamp fits the shape of flat cables. Many technicians use a fiber optic drop wire clamp to support cables on walls, poles, or buildings.

Proper use of these clamps helps maintain signal quality and reduces cable wear.

Key Takeaways

- Flat fiber optic drop wire clamps keep flat cables in place.

- These clamps stop cables from sagging, bending, or getting scratched.

- They also help keep the signal strong and clear.

- Pick clamps that fit your cable and work for your area.

- Follow each step and safety rule when installing the clamps.

- Check clamps often for damage to keep cables safe and working well.

Flat Fiber Optic Drop Wire Clamp Main Functions

Securing Flat Fiber Optic Drop Cables

A flat fiber optic drop wire clamp holds flat fiber cables tightly in place. This clamp grips the cable and keeps it from moving or slipping. Installers use these clamps to attach cables to poles, walls, or other surfaces. The clamp’s design matches the shape of flat cables, which helps create a secure fit. When the clamp holds the cable firmly, it prevents the cable from falling or shifting during bad weather or strong winds.

Tip: Always check that the clamp fits the cable size before installation. A good fit ensures the cable stays secure.

Preventing Cable Damage and Sagging

Flat fiber optic drop wire clamps protect cables from damage. When cables hang loosely, they can bend, twist, or rub against rough surfaces. This can cause the cable to break or lose signal quality. The clamp supports the cable and spreads out the weight. This support stops the cable from sagging or pulling at the ends. Installers use these clamps to keep cables straight and safe, even over long distances.

A table below shows how clamps help prevent common cable problems:

| Problem | How the Clamp Helps |

|---|---|

| Sagging | Holds cable up and tight |

| Abrasion | Stops cable from rubbing |

| Bending | Keeps cable straight |

| Pulling | Reduces stress on cable ends |

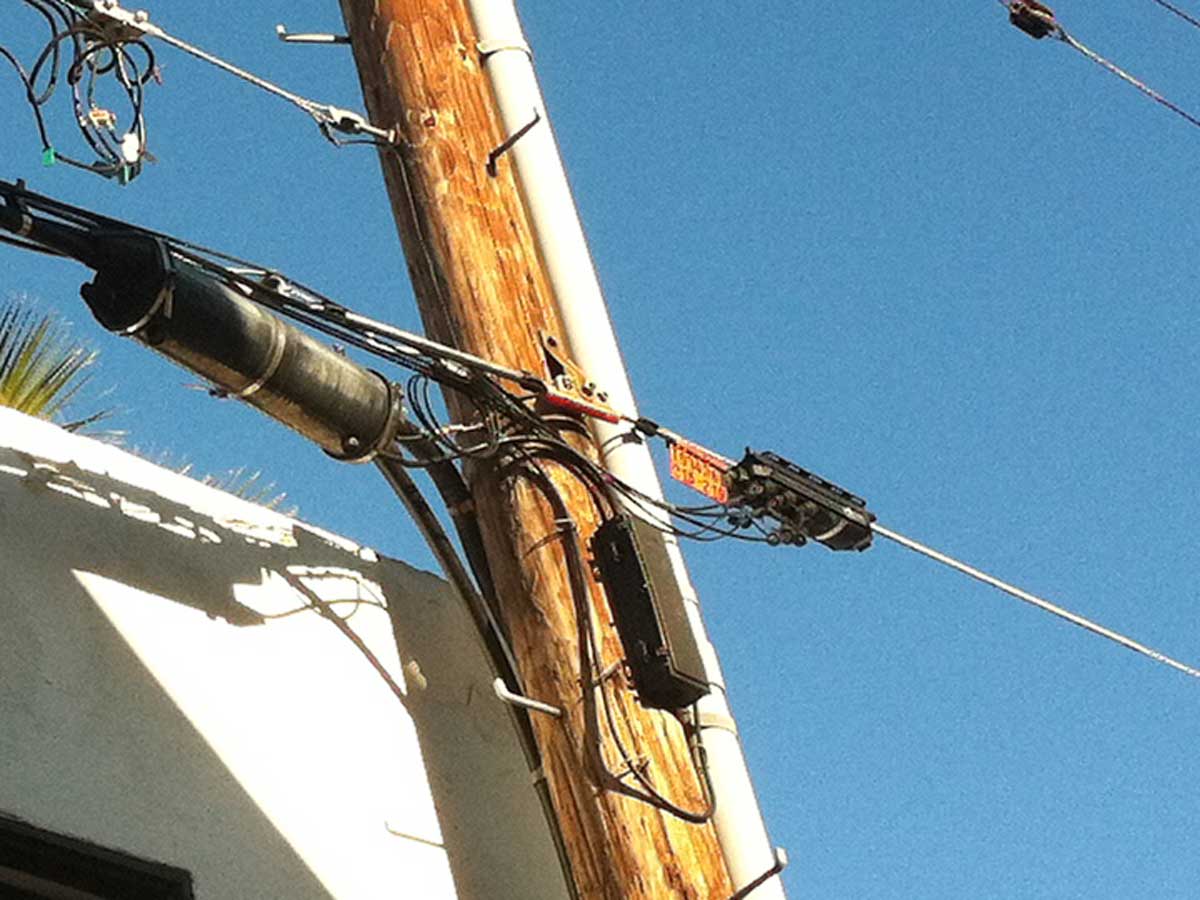

Typical Installation Environments

People use flat fiber optic drop wire clamps in many places. These clamps work well outdoors and indoors. Installers often use them on utility poles, building walls, and inside homes or offices. The clamp’s strong grip makes it useful in areas with wind, rain, or snow. Many fiber networks in cities and rural areas rely on these clamps to keep cables safe and working.

- Common installation environments include:

- Telephone poles along streets

- Building exteriors and rooftops

- Inside communication rooms

- Residential and commercial buildings

Note: Choosing the right clamp for each environment helps protect the cable and ensures a long service life.

Flat Fiber Optic Drop Wire Clamp Types and Materials

Common Clamp Designs

Manufacturers create several designs for flat fiber optic drop wire clamps. Some clamps use a wedge shape that grips the cable tightly. Others use a simple plate and bolt system. Many clamps have a self-adjusting feature. This feature lets the clamp fit different cable sizes. Some designs include a hook or eyelet for easy attachment to poles or walls. Installers often choose the design based on the type of cable and the installation site.

- Popular clamp designs:

- Wedge-type clamps

- Plate and bolt clamps

- Self-adjusting clamps

- Clamps with hooks or eyelets

Note: The right design helps keep the cable secure and makes installation easier.

Materials Used in Manufacturing

Manufacturers use strong materials to make these clamps. Stainless steel is a common choice because it resists rust and lasts a long time. Some clamps use aluminum, which is lightweight and strong. Plastic or polymer materials also appear in some designs. These materials work well in areas with less stress or where weight matters. The choice of material affects the clamp’s strength and how long it lasts.

| Material | Main Benefit | Typical Use |

|---|---|---|

| Stainless Steel | Rust resistance | Outdoor installations |

| Aluminum | Lightweight | Poles and buildings |

| Plastic/Polymer | Non-conductive, light | Indoor use |

Application-Specific Variations

Different jobs need different types of flat fiber optic drop wire clamp. Outdoor installations often need clamps that resist weather and UV rays. Indoor jobs may use lighter clamps. Some clamps have extra coatings for harsh environments. Others have special shapes for tight spaces or unique mounting needs. Installers pick the clamp that matches the cable type and the job site.

- Examples of application-specific features:

- UV-resistant coatings for outdoor use

- Compact size for small spaces

- Extra grip for heavy cables

Tip: Always match the clamp to the cable and the environment for the best results.

Flat Fiber Optic Drop Wire Clamp Installation Guide

Step-by-Step Installation

Installing a flat fiber optic drop wire clamp requires careful attention. Technicians follow a series of steps to ensure a secure and reliable connection.

- Prepare the Cable:

Clean the flat fiber cable. Remove any dirt or moisture. This step helps the clamp grip the cable tightly. - Select the Right Clamp:

Choose a clamp that matches the cable size and type. The clamp should fit snugly around the flat cable. - Position the Clamp:

Place the clamp at the correct spot on the cable. Most installers position it near the end of the cable, close to the support structure. - Insert the Cable:

Slide the flat fiber cable into the clamp. Make sure the cable sits flat and straight inside the clamp. - Secure the Clamp:

Tighten the clamp using the built-in mechanism. Some clamps use bolts, while others use a wedge or self-locking system. - Attach to Support:

Fix the clamp to the pole, wall, or other structure. Use the hook, eyelet, or mounting hole provided on the clamp. - Check the Installation:

Inspect the clamp and cable. Ensure the cable does not move or sag. Adjust if needed.

Tip: Always follow the manufacturer’s instructions for each flat fiber optic drop wire clamp.

Safety Considerations

Safety plays a key role during installation. Technicians must protect themselves and the cable.

- Wear gloves to avoid cuts from sharp edges.

- Use safety glasses when working near poles or overhead lines.

- Avoid installing clamps during wet or stormy weather.

- Check for nearby electrical wires before starting work.

- Use ladders or lifts safely when working at heights.

- Never pull or twist the fiber cable too hard.

A table below lists common safety tips:

| Safety Tip | Why It Matters |

|---|---|

| Wear gloves | Prevents hand injuries |

| Use safety glasses | Protects eyes from debris |

| Avoid wet weather | Reduces slip risk |

| Check for power lines | Prevents electric shock |

| Use ladders properly | Prevents falls |

Note: Safe installation protects both the technician and the fiber network.

Choosing the Right Flat Fiber Optic Drop Wire Clamp

Factors to Consider

Selecting the best clamp for a fiber installation project requires careful thought. Installers look at several important factors before making a choice. The size and shape of the cable matter most. A clamp that fits well will hold the cable securely. The weight of the cable also affects the choice. Heavier cables need stronger clamps. The type of support structure, such as a pole or wall, can change which clamp works best. Cost and availability may also play a role in the decision.

Tip: Always check the manufacturer’s recommendations for each clamp model.

Matching Clamp to Cable Type

Not all clamps fit every cable. Installers must match the clamp to the cable type. Flat cables need a flat fiber optic drop wire clamp. Using the wrong clamp can cause the cable to slip or get damaged. Some cables have extra layers for protection. These may need a larger or adjustable clamp. The table below shows how to match clamps to cable types:

| Cable Type | Recommended Clamp Type |

|---|---|

| Flat fiber cable | Flat fiber optic drop wire clamp |

| Round fiber cable | Round drop wire clamp |

| Armored cable | Heavy-duty clamp |

A good match keeps the cable safe and helps the network work well.

Environmental and Load Requirements

The environment plays a big role in clamp selection. Outdoor installations face rain, wind, and sunlight. Installers choose clamps made from stainless steel or UV-resistant materials for these places. Indoor jobs may use lighter or plastic clamps. The load, or weight, that the clamp must hold also matters. Strong winds or long cable runs increase the load. Installers pick clamps that can handle these forces. They check the clamp’s rated load before use.

Note: Using the right clamp for the environment and load helps prevent cable failure and service interruptions.

A flat fiber optic drop wire clamp helps keep flat fiber cables secure and safe in many settings. This tool prevents cable damage and supports reliable network performance. Careful selection and correct installation protect both the cable and the network. Readers should always check product details and ask experts for advice when planning a new installation.

FAQ

What is the main purpose of a flat fiber optic drop wire clamp?

A flat fiber optic drop wire clamp holds flat fiber cables in place. It keeps cables secure and prevents them from moving or getting damaged. This clamp helps maintain signal quality in fiber optic networks.

Can one clamp fit all types of flat fiber cables?

No, not every clamp fits all flat fiber cables. Installers must check the cable size and shape before choosing a clamp. Using the correct clamp ensures a secure fit and protects the cable.

Where do technicians usually install these clamps?

Technicians often install these clamps on utility poles, building walls, or inside communication rooms. The clamp works well both outdoors and indoors. It helps keep cables safe in many different environments.

How do you know if a clamp is strong enough?

Installers check the clamp’s rated load. Manufacturers provide this information. The clamp must support the cable’s weight and handle weather conditions. A table below shows what to look for:

| Checkpoint | Why It Matters |

|---|---|

| Rated Load | Supports cable weight |

| Material Type | Handles environment |

Do flat fiber optic drop wire clamps need maintenance?

Most clamps need little maintenance. Technicians should inspect them during routine checks. They look for rust, cracks, or loose fittings. Regular inspection helps prevent cable problems and keeps the network running smoothly.

By: Consult

Tel: +86 574 27877377

Mb: +86 13857874858

E-mail: henry@cn-ftth.com

Youtube: DOWELL

Pinterest: DOWELL

Facebook: DOWELL

Linkedin: DOWELL

Post time: Jun-13-2025