Stainless Steel Strapping Banding Roll gives workers the power to secure heavy loads with confidence. Many industries rely on this solution to hold timber, metal coils, concrete blocks, and equipment in place. Its strength and resistance to harsh weather help keep loads stable during transport and storage.

Key Takeaways

- Stainless steel strapping offers unmatched strength and durability, making it ideal for securing heavy and sharp-edged loads safely during transport and storage.

- Its excellent resistance to rust, acid, and harsh weather conditions ensures reliable performance outdoors and in marine environments.

- Using the right grade, size, and tools, along with proper load preparation and regular inspection, guarantees a secure hold and prevents accidents.

Why Choose Stainless Steel Strapping Banding Roll for Heavy Loads

High Tensile Strength and Durability

Stainless Steel Strapping Banding Roll stands out for its incredible strength. Industries choose this material because it holds the heaviest loads without stretching or breaking. Tests show that it can handle forces much greater than 8.0 KN, with some samples reaching 11.20 KN before breaking. This high tensile strength means workers can trust it to secure sharp-edged or bulky items. The band also stretches up to 25% before breaking, which adds a layer of safety during transport. Many construction and government projects rely on this strapping for its proven durability.

When safety and reliability matter most, this strapping delivers peace of mind.

Corrosion and Weather Resistance

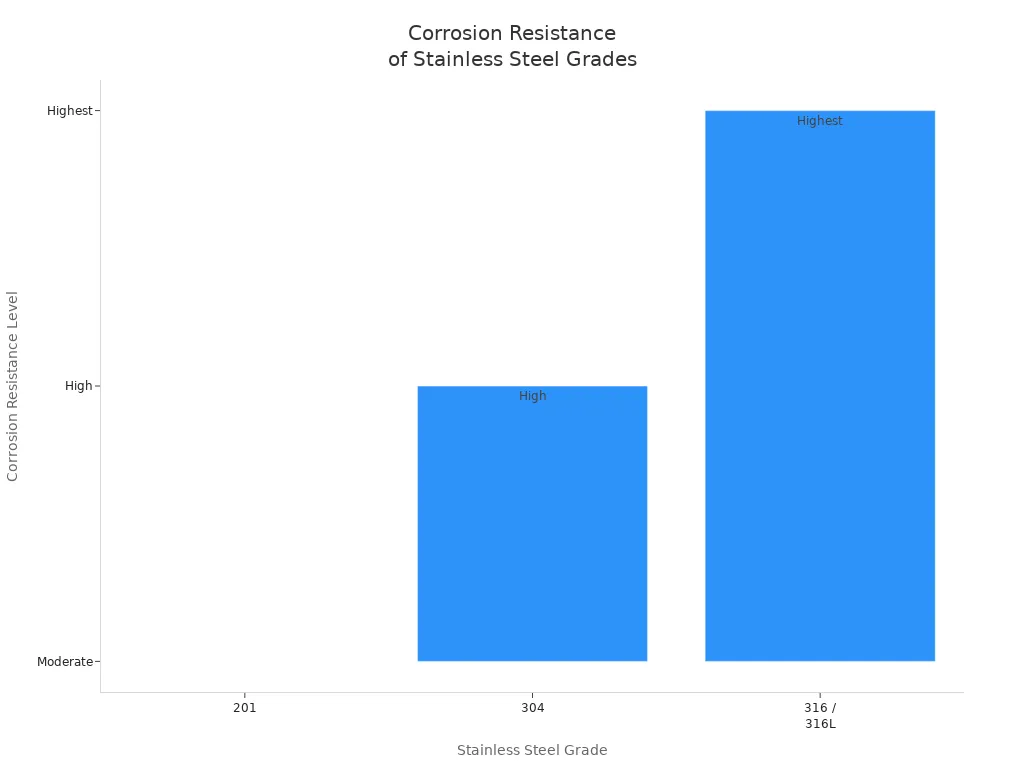

Outdoor and marine environments challenge any material. Stainless Steel Strapping Banding Roll resists rust, acid, and even UV rays. It performs well in rain, snow, and salty air. Grades like 304 and 316 offer the highest corrosion resistance, making them perfect for harsh conditions. The table below shows how different grades compare:

| Stainless Steel Grade | Corrosion Resistance Level | Typical Application |

|---|---|---|

| 201 | Moderate | General outdoor use |

| 304 | High | Outdoor, moist, or corrosive areas |

| 316 | Highest | Marine and chloride-rich settings |

Performance Advantages Over Other Materials

Stainless Steel Strapping Banding Roll outperforms plastic and polyester strapping in many ways. It keeps its shape and tension, even after many load cycles. Unlike polyester, it does not stretch or weaken under heavy weight. Its rigid structure protects against sharp edges and high temperatures. Workers find it ideal for loads that travel long distances or face rough handling. The table below highlights the typical uses for each strapping type:

| Strap Type | Typical Use |

|---|---|

| Steel Strapping | Heavy to Extra Heavy Duty |

| Polyester Strapping | Medium to Heavy Duty |

| Polypropylene | Light to Medium Duty |

Choosing stainless steel means choosing strength, safety, and long-term value.

How to Use Stainless Steel Strapping Banding Roll Effectively

Selecting the Appropriate Grade and Size

Choosing the right grade and size sets the foundation for a secure load. Workers often select grades like 201, 304, or 316 for their strength and corrosion resistance. Each grade fits different environments. For example, 304 and 316 handle harsh weather and marine conditions. The width and thickness of the band also matter. Thicker and wider bands support heavier loads and resist shock. The table below shows common sizes used in heavy-duty applications:

| Width (inches) | Thickness (inches) | Description/Grade |

|---|---|---|

| 1/2 | 0.020, 0.023 | High tensile, AAR-approved |

| 5/8 | Various | High tensile, AAR-approved |

| 3/4 | Various | High tensile, AAR-approved |

| 1 1/4 | 0.025–0.044 | High tensile, AAR-approved |

| 2 | 0.044 | High tensile, AAR-approved |

Selecting the right combination ensures the Stainless Steel Strapping Banding Roll performs at its best.

Preparing and Positioning the Load

Proper preparation and positioning prevent accidents and keep loads stable. Workers stack items evenly and use racks or dunnage for support. Balanced loads reduce the risk of shifting or rolling. They follow securement protocols, including the correct number and placement of bands. Safety always comes first. The table below highlights common risks and how to avoid them:

| Potential Risks of Improper Load Positioning | Mitigation Measures |

|---|---|

| Falling or rolling coils | Use racks, balance loads, follow protocols |

| Banding failures | Follow procedures, use edge protectors, inspect bands |

| Equipment failure | Use rated equipment, train operators, inspect tools |

| Pinch points | Maintain safe positions, stay alert |

| Sharp edges | Wear gloves, handle carefully |

| Struck-by accidents | Control access, use barriers |

| Unsafe stacking | Limit height, use racks, keep areas clear |

| Unsafe operator positioning | Keep safe distances, avoid standing under loads |

| Lack of lockout/tagout | Enforce safety procedures |

Tip: Always wear gloves and eye protection when handling bands and loads.

Measuring, Cutting, and Handling the Band

Accurate measuring and careful handling ensure a tight, secure fit. Workers measure the band length needed to wrap around the load with a little extra for sealing. They use heavy-duty cutters to make clean cuts. Handling the band with care prevents injuries from sharp edges. Safety steps include:

- Wearing sturdy gloves to protect hands.

- Using eye protection to guard against snapping bands.

- Cutting or bending band ends inward to avoid sharp points.

- Handling coated bands gently to preserve finishes.

Safety first! Proper handling keeps everyone safe and the job on track.

Applying, Tensioning, and Sealing the Band

Applying the Stainless Steel Strapping Banding Roll requires focus and the right tools. Workers follow these steps for a secure hold:

- Place the band around the load and thread it through a seal or buckle.

- Use a tensioning tool to pull the band tight. This step keeps the load from shifting.

- Seal the band by hammering down the wings of the seal or using a sealer tool. This action locks the band in place.

- Cut off any extra band for a neat finish.

- Double-check the seal to make sure it holds strong.

The right tools make a difference. Tensioners, sealers, and heavy-duty cutters help workers apply the band safely and efficiently. Some teams use battery-powered tools for extra holding power.

Note: Avoid over-tensioning. Too much force can break the band or damage the load.

Inspecting and Testing the Secured Load

Inspection brings peace of mind. Workers check every band for tightness and proper sealing. They look for signs of damage or loose ends. Testing the load by gently moving it confirms stability. Regular inspections catch problems early and prevent accidents.

- Check all bands for secure seals.

- Look for sharp edges or exposed ends.

- Test the load for movement.

- Replace any damaged bands right away.

A well-secured load stands up to transport and storage challenges. Every step, from selection to inspection, builds confidence and safety.

Stainless Steel Strapping Banding Roll stands as a trusted choice for heavy load security. Industry standards like ASTM D3953 and certifications such as ISO 9001, CE, and AAR support its quality. Teams who follow best practices achieve safe, reliable results and inspire confidence in every project.

FAQ

How does stainless steel strapping help in extreme weather?

Stainless steel strapping stands strong in rain, snow, and heat. Its resistance to rust and UV rays keeps heavy loads safe, no matter the weather.

Can workers reuse stainless steel strapping after removal?

Workers should use new strapping for each job. Reusing strapping may weaken its strength. Fresh bands ensure the highest level of safety and reliability every time.

What tools do workers need for proper installation?

Workers need tensioners, sealers, and heavy-duty cutters. These tools help them apply, tighten, and secure the band quickly and safely for every heavy load.

Tip: Using the right tools inspires confidence and guarantees a secure hold every time.

Post time: Aug-20-2025