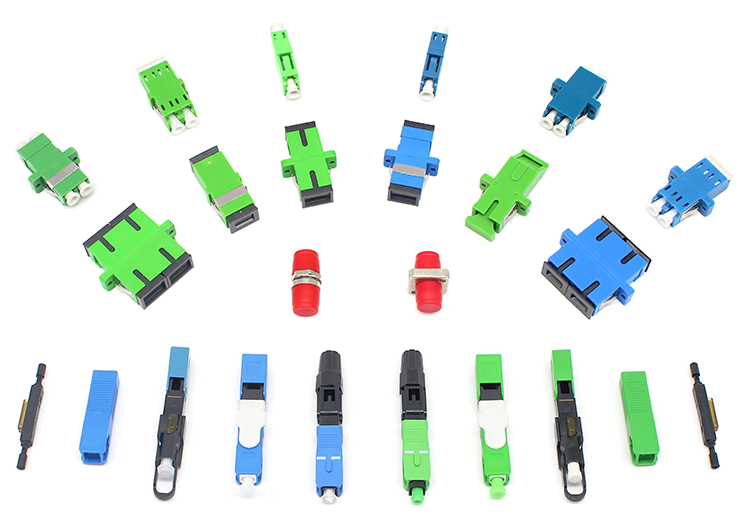

Signal loss is a major challenge in maintaining reliable network performance. Precision fiber optic adapters are essential in addressing this issue. These components, including fiber optic adapter female options, are designed to align and secure connections, ensuring seamless data transmission and preventing signal degradation. For example, SC Simplex adapters and Sc upc adapters are specifically crafted for high-performance environments such as data centers and telecommunications. Their durable design minimizes the risk of signal loss and ensures stable connectivity. Choosing high-quality fiber adapters, like those offered by Dowell, is critical for preserving signal integrity and achieving optimal network efficiency.

Key Takeaways

- Pick good-quality fiber adapters from trusted brands like Dowell. This helps reduce signal loss and keeps the network working well.

- Clean and check fiber adapter ends often to stop dirt. Dirt can block light and weaken the signal.

- Learn about signal loss types, like insertion loss and return loss. This helps you understand how fiber optic systems work.

- Make sure fiber adapters match the fiber type and connector standards. This prevents problems and keeps signals strong.

- Handle and store fiber adapters carefully to keep them in good shape. This also makes them last longer.

Understanding Signal Loss in Fiber Adapters

Defining Signal Loss in Fiber Adapters

Signal loss in fiber adapters refers to the reduction in optical signal strength as it passes through a connection point. This phenomenon occurs due to imperfections in alignment, material quality, or environmental factors. Signal loss is typically measured in decibels (dB), providing a quantifiable metric for evaluating the performance of fiber optic systems.

Insertion loss and attenuation are two key parameters that define signal loss. Insertion loss represents the energy lost when a signal travels through a connector or splice, while attenuation measures the reduction in signal strength during transmission. Both factors play a critical role in determining the efficiency of fiber adapters.

Types of Signal Loss: Insertion Loss and Return Loss

Insertion loss and return loss are the primary types of signal loss encountered in fiber optic systems.

| Term | Definition |

|---|---|

| Insertion Loss | The loss of an optical signal due to the insertion of components like connectors or splices. |

| Return Loss | The amount of signal reflected back toward the source, which can interfere with data transmission. |

Insertion loss is influenced by the length and quality of the cable, as longer cables tend to incur greater losses. Return loss, on the other hand, arises from poor connector interfaces or misaligned connections, leading to signal reflection. Both types of loss can degrade network performance if not properly managed.

Effects of Signal Loss on Network Performance

Signal loss directly impacts network reliability and efficiency. Excessive loss can lead to packet loss, where data packets fail to reach their destination, disrupting real-time applications like video conferencing.

- Packet Loss Rate: High signal loss increases the percentage of lost packets, reducing data integrity.

- Mean Time Between Failures (MTBF): Frequent signal degradation lowers MTBF, indicating reduced network reliability.

- Mean Time to Repair (MTTR): Prolonged repair times due to signal loss can delay network recovery, affecting overall performance.

By selecting precision fiber adapters, such as those offered by Dowell, users can minimize signal loss and ensure stable connectivity across their networks.

Key Factors That Contribute to Signal Loss

Material and Build Quality of Fiber Adapters

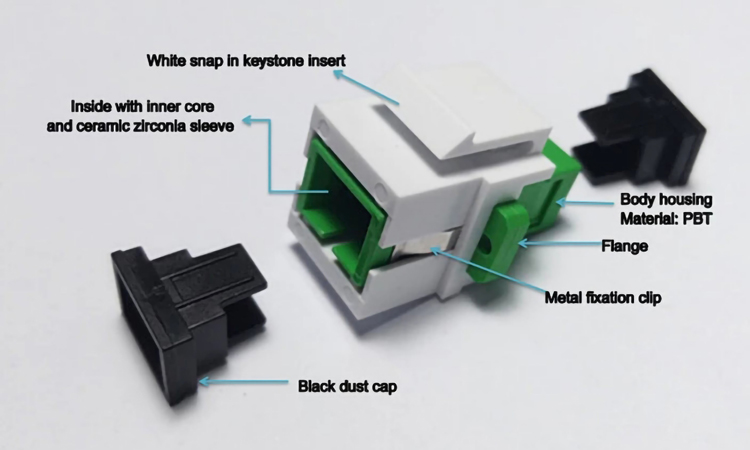

The material and structural integrity of fiber adapters significantly influence signal transmission efficiency. High-quality materials, such as ceramic or zirconia ferrules, ensure minimal light dispersion and reduce insertion loss. Studies have shown that adapters made from substandard materials can degrade signal quality, particularly in high-speed networks. For instance, erbium-doped fiber amplifiers, which rely on precise material properties, demonstrate superior performance when paired with premium adapters.

Mechanical durability also plays a critical role. Adapters designed for frequent use, such as MTP connectors, exhibit low insertion loss and enhanced longevity. These features make them ideal for environments requiring consistent performance, such as data centers. Selecting adapters with robust construction ensures long-term reliability and minimizes the risk of signal degradation.

Connector Interface Alignment and Precision

Precise alignment of connector interfaces is essential for maintaining signal integrity. Misaligned connections can lead to increased insertion loss and return loss, disrupting data transmission. Engineering tests validate this by demonstrating that well-aligned connectors achieve insertion losses below 1.5 dB and return loss values of at least -30 dB.

| Alignment Factor | Impact on Performance |

|---|---|

| Precise Alignment | Reduces insertion loss and ensures efficient light coupling between connectors. |

| Misalignment | Causes signal reflection, leading to higher return loss and potential data errors. |

| Installation Accuracy | Proper tools and techniques during installation prevent alignment-related issues. |

Investing in adapters with high-precision alignment mechanisms ensures optimal performance. Brands like Dowell offer solutions engineered to meet these stringent requirements, providing users with reliable connectivity.

Cleanliness of Fiber Adapter Endfaces

The cleanliness of fiber adapter endfaces directly affects signal quality. Even minor contaminants, such as dust or oil, can disrupt light transmission, leading to signal loss. Regular inspection using specialized tools is crucial to maintaining clean endfaces.

- Contaminants can trap laser light, converting it into heat and potentially damaging the fiber.

- Scratches on endfaces scatter light, causing distortion and reducing signal clarity.

- Dirty endfaces increase the risk of equipment failure and operational downtime.

Users should adopt a proactive approach to cleaning and maintenance. This includes using lint-free wipes and isopropyl alcohol to remove impurities without causing additional contamination. By prioritizing cleanliness, network operators can safeguard their systems against performance issues.

Environmental Factors and Their Impact on Signal Integrity

Environmental conditions play a significant role in the performance and reliability of fiber adapters. Factors such as temperature fluctuations, humidity levels, and exposure to contaminants can directly impact signal integrity. Understanding these influences helps network operators mitigate risks and maintain optimal performance.

Temperature Variations

Temperature changes can alter the physical and electrical properties of fiber adapters. High temperatures accelerate material degradation, reducing insulation and conductivity. This can lead to early component failure and diminished performance. On the other hand, low temperatures may cause materials to contract, potentially misaligning connectors and increasing insertion loss.

Tip: Choose adapters with robust thermal resistance to ensure consistent performance in environments with extreme temperature variations.

Humidity and Moisture

Humidity introduces moisture into the system, which can corrode metal components and cause electrical leakage. Over time, this compromises the functionality of fiber adapters and increases the risk of signal loss. Humidity cycling, where moisture levels fluctuate, can have cumulative effects, further degrading component reliability.

- Key Impacts of Humidity:

- Corrosion of metallic parts.

- Increased electrical resistance and leakage.

- Accelerated material wear due to moisture absorption.

Combined Effects of Temperature and Humidity

When temperature and humidity fluctuate together, the impact on fiber adapters becomes more pronounced. This cycling effect can distort signals by altering electrical properties like resistance and capacitance. Such conditions demand high-quality adapters designed to withstand environmental stress.

Dowell’s precision fiber adapters are engineered to perform reliably under challenging environmental conditions. Their durable construction and advanced materials ensure minimal signal loss, even in extreme settings. By selecting adapters with proven resistance to environmental factors, users can safeguard their networks against performance degradation.

Expert Tips for Selecting Precision Fiber Adapters

Choosing High-Quality Fiber Adapters from Trusted Brands like Dowell

Selecting high-quality fiber adapters is essential for maintaining network performance and reliability. Trusted brands like Dowell offer precision-engineered solutions designed to minimize signal loss and ensure seamless connectivity. High-quality adapters undergo rigorous testing to meet industry standards, providing users with confidence in their performance.

- Case Study:

E-Fiber, a fiber-to-the-home provider in the Netherlands, faced challenges in optimizing network rollouts across diverse regions while managing costs. By utilizing high-quality products from CommScope, they achieved improved performance and reliability. This demonstrates the value of investing in premium adapters from reputable brands.

Dowell’s fiber adapters are designed with advanced materials and precision alignment mechanisms, ensuring long-term durability and consistent performance. By choosing products from trusted manufacturers, users can reduce the risk of network disruptions and enhance overall efficiency.

Ensuring Compatibility with Fiber Types and Connector Standards

Compatibility is a critical factor when selecting fiber adapters. Adapters must align with the specific fiber types and connector standards used in a network to ensure optimal performance. Mismatched components can lead to increased insertion loss and signal degradation.

The following table highlights key compatibility standards and their focus areas:

| Standard/Specification | Focus Area | Status |

|---|---|---|

| IEC 60793-1-1 | Fiber measurement methods and test procedures | Published (June 2022) |

| IEC 60794-1-1 | General specifications for fiber cables | Final stages of restructuring (mid-2023) |

| IEC 60793-2-50 | Specifications for singlemode fiber | Committee draft for vote (early 2024) |

| IEC 61300-1 | Environmental testing of components | Under development |

| IEC 61300-3-35 | Visual inspection of fiber connector endfaces | Ongoing improvements |

Adapters from Dowell are designed to comply with these standards, ensuring seamless integration with various fiber types and connector interfaces. This compatibility reduces the risk of performance issues and simplifies network deployment.

Evaluating Durability and Performance Specifications

Durability and performance are key considerations when selecting fiber adapters. Adapters must withstand mechanical stress, environmental conditions, and extended operational use without compromising signal integrity. Long-term durability studies provide valuable insights into the reliability of fiber adapters under continuous operation.

| Test Type | Purpose |

|---|---|

| Mandatory Mechanical Tests | Verify long-term integrity through mechanical stress evaluations. |

| Environmental Stress Tests | Assess performance under varying environmental conditions to ensure reliability. |

| Life Tests | Validate long-term reliability by simulating extended operational conditions. |

| Live Tests | Evaluate performance under actual operational conditions with high-speed signals. |

| Space Applications Tests | Ensure reliability in extreme conditions such as radiation and thermal vacuum environments. |

| Screening Tests | Continuous quality assurance for production lots to identify defects and ensure reliability. |

Dowell’s fiber adapters undergo extensive testing to meet these rigorous standards. Their robust construction and high-performance materials ensure reliable operation in demanding environments. By evaluating durability and performance specifications, users can select adapters that deliver consistent results and minimize maintenance requirements.

Verifying Industry Certifications and Standards Compliance

Industry certifications and standards compliance play a pivotal role in ensuring the reliability and performance of fiber adapters. These certifications validate that the adapters meet stringent requirements for quality, safety, and functionality, making them suitable for high-performance networks. Selecting adapters that adhere to recognized standards minimizes the risk of signal loss and ensures seamless integration into existing systems.

Importance of Certifications in Fiber Optic Systems

Certifications provide assurance that fiber adapters have undergone rigorous testing and meet established benchmarks. They serve as a guarantee of quality, enabling network operators to trust the components they deploy. Certified adapters reduce the likelihood of compatibility issues and ensure consistent performance across diverse applications.

Tip: Always verify the certifications of fiber adapters before purchase to avoid potential network disruptions caused by substandard components.

Key Certification Bodies and Standards

Several organizations oversee the certification and standardization of fiber optic systems. These bodies establish guidelines that manufacturers must follow to ensure their products meet industry expectations. The table below highlights some of the most influential certification bodies and compliance metrics:

| Certification Body/Standard | Description |

|---|---|

| Fiber Optic Association (FOA) | Provides certification programs for technicians to ensure compliance with industry standards. |

| Telecommunications Industry Association (TIA) | Offers standards and certifications relevant to fiber optic installations. |

| International Telecommunication Union (ITU) | Develops global standards, including ITU-T G.652 for single-mode optical fibers. |

| Institute of Electrical and Electronics Engineers (IEEE) | Governs Ethernet networking protocols through IEEE 802.3, impacting fiber optic systems. |

| Compliance Metrics | Standards such as ANSI/TIA-568, IEC 61754, and ISO/IEC 11801 ensure performance and safety of fiber optic products. |

Adapters that comply with these standards demonstrate superior performance and reliability. For instance, adherence to ANSI/TIA-568 ensures optimal cable management and signal transmission, while compliance with IEC 61754 guarantees precise connector interfaces.

Benefits of Standards Compliance

Fiber adapters that meet industry standards offer several advantages:

- Enhanced Signal Integrity: Certified adapters minimize insertion loss and return loss, ensuring stable data transmission.

- Improved Compatibility: Compliance with global standards facilitates seamless integration with various fiber types and network configurations.

- Long-Term Reliability: Adapters designed to meet rigorous standards exhibit greater durability and resistance to environmental stress.

Dowell’s fiber adapters are engineered to comply with these certifications, providing users with confidence in their network infrastructure. By prioritizing certified products, network operators can safeguard their systems against performance degradation and operational downtime.

Best Practices for Maintaining and Optimizing Fiber Adapters

Regular Cleaning and Inspection of Fiber Adapters

Maintaining the cleanliness of fiber adapters is essential for preserving signal integrity and preventing performance issues. Dust, oil, and other contaminants can accumulate on connector endfaces, leading to signal loss and potential equipment damage. Regular cleaning and inspection ensure that these issues are addressed before they impact network performance.

Experts recommend inspecting every connector endface before connecting it to any equipment. This practice helps identify contaminants or scratches that could disrupt light transmission. Cleaning techniques should follow a structured approach. Dry cleaning methods, such as using lint-free wipes, should be the first step. If contaminants persist, wet cleaning with isopropyl alcohol can be employed, ensuring no residue remains.

| Best Practice | Description |

|---|---|

| Regular Inspection | Inspect every connector endface before connecting to ensure cleanliness. |

| Cleaning Techniques | Start with dry cleaning, followed by wet cleaning if necessary. |

| Importance of Maintenance | Prevent fiber-related problems and maintain network performance. |

Network operators should also adopt rigorous cleaning procedures for multi-fiber connectors like MPO adapters. These connectors require specialized tools to clean all fiber channels effectively. By prioritizing regular cleaning and inspection, organizations can extend the lifespan of their fiber adapters and maintain optimal signal quality.

Monitoring Signal Performance and Testing for Degradation

Monitoring the performance of fiber adapters is a proactive approach to identifying and addressing potential issues. Signal degradation can occur over time due to wear, environmental factors, or improper handling. Regular testing ensures that any decline in performance is detected early, allowing for timely corrective actions.

Technicians should use optical power meters and OTDR (Optical Time-Domain Reflectometer) devices to measure signal strength and pinpoint areas of loss. These tools provide accurate data on insertion loss and return loss, enabling precise diagnostics. For example, a sudden increase in insertion loss may indicate misalignment or contamination, while high return loss could suggest poor connector interfaces.

Tip: Schedule periodic performance tests to track signal quality trends and identify degradation before it affects network reliability.

In addition to testing, maintaining detailed records of signal performance can help identify patterns and predict potential failures. This data-driven approach allows network operators to implement preventive measures, ensuring consistent performance and minimizing downtime.

Proper Handling and Storage of Fiber Adapters

Proper handling and storage practices play a crucial role in preserving the functionality of fiber adapters. Mishandling can lead to physical damage, misalignment, or contamination, all of which contribute to signal loss. Adopting best practices for handling and storage minimizes these risks and ensures long-term reliability.

When handling fiber adapters, technicians should avoid touching the connector endfaces directly. Oils and debris from hands can transfer to the connectors, compromising their performance. Using protective caps during transportation and storage prevents exposure to dust and other contaminants.

Storage conditions also impact the longevity of fiber adapters. Adapters should be stored in a clean, dry environment away from extreme temperatures and humidity. Organizing adapters in labeled compartments or cases reduces the risk of damage and simplifies inventory management.

- Key Handling Tips:

- Avoid direct contact with connector endfaces.

- Use protective caps during transportation and storage.

- Handle adapters with clean, dry hands or wear gloves.

By following these handling and storage guidelines, network operators can protect their fiber adapters from unnecessary wear and tear, ensuring consistent performance and reducing maintenance costs.

Avoiding Excessive Bending and Stress on Fiber Cables

Excessive bending and stress on fiber cables can significantly impact signal integrity and network performance. Fiber optic cables are designed to transmit light signals with minimal loss, but improper handling can disrupt this process. Understanding the risks associated with bending and stress is essential for maintaining the reliability of fiber optic systems.

The Impact of Excessive Bending on Signal Integrity

Fiber optic cables have a minimum bend radius, which defines the smallest curve they can tolerate without signal degradation. Bending a cable beyond this radius can cause microbends or macrobends, leading to increased attenuation and signal loss. Microbends are small, localized distortions in the fiber core, while macrobends are larger, visible bends that cause light to escape from the core.

Tip: Always check the manufacturer’s specifications for the minimum bend radius of a cable. Adhering to these guidelines ensures optimal signal transmission.

Stress and Its Effect on Fiber Cables

Physical stress, such as pulling, twisting, or compressing fiber cables, can weaken their structural integrity. Over time, this stress may lead to fractures or permanent deformation, compromising the cable’s performance. Stress can also misalign the fiber core, increasing insertion loss and return loss.

- Common Causes of Stress on Fiber Cables:

- Improper installation techniques, such as over-tightening cable ties.

- Excessive pulling during cable deployment.

- Storing cables in cramped or unsuitable conditions.

Best Practices for Preventing Bending and Stress

Implementing proper handling and installation practices can prevent damage to fiber cables. The following best practices help maintain the longevity and performance of fiber optic systems:

- Maintain Proper Bend Radius: Use cable management tools like bend radius guides to ensure cables do not exceed their specified limits.

- Avoid Tight Cable Ties: Use Velcro straps or loose cable ties to secure cables without applying excessive pressure.

- Use Protective Conduits: Install cables in conduits or trays to shield them from external forces and environmental hazards.

- Plan Cable Routes Carefully: Avoid sharp corners and tight spaces when designing cable pathways.

Dowell’s Solutions for Stress-Free Fiber Management

Dowell offers a range of fiber management solutions designed to minimize bending and stress on cables. Their products include bend-insensitive fiber cables and advanced cable routing systems, ensuring reliable performance even in challenging environments. By incorporating Dowell’s precision-engineered solutions, network operators can safeguard their infrastructure against signal loss and degradation.

Note: Investing in high-quality fiber adapters and cables from trusted brands like Dowell reduces the risk of damage caused by improper handling.

Maintaining proper handling practices and using reliable products ensures the long-term efficiency of fiber optic networks. By avoiding excessive bending and stress, network operators can enhance signal integrity and reduce maintenance costs.

Selecting precision fiber adapters is essential for maintaining signal integrity and preventing network disruptions. Industry reports highlight that signal loss and reflections at connector interfaces significantly hinder performance, emphasizing the importance of precise alignment and high-quality components. Regular maintenance, such as cleaning and inspection, further ensures long-term reliability. By prioritizing trusted brands like Dowell, network operators can achieve consistent performance and safeguard their systems against degradation. Investing in quality solutions not only enhances efficiency but also reduces operational risks.

FAQ

What is the primary purpose of a precision fiber adapter?

Precision fiber adapters align and connect fiber optic cables to ensure efficient light transmission. They minimize signal loss and maintain network performance by providing a stable and precise interface between connectors.

How can users identify high-quality fiber adapters?

High-quality fiber adapters often come from trusted brands like Dowell. They feature durable materials, precise alignment mechanisms, and certifications that meet industry standards, ensuring reliable performance.

Why is cleaning fiber adapter endfaces important?

Contaminants like dust or oil on endfaces disrupt light transmission, causing signal loss. Regular cleaning with lint-free wipes or isopropyl alcohol ensures optimal performance and prevents equipment damage.

What certifications should fiber adapters comply with?

Fiber adapters should comply with standards like ANSI/TIA-568, IEC 61754, and ISO/IEC 11801. These certifications guarantee compatibility, durability, and reliable signal transmission in various network environments.

How do environmental factors affect fiber adapters?

Temperature fluctuations, humidity, and contaminants can degrade fiber adapters. Choosing adapters with robust environmental resistance, such as those from Dowell, ensures consistent performance under challenging conditions.

Post time: May-07-2025