Selecting the right Fiber Optic Splice Closure is paramount for ensuring network reliability, longevity, and future scalability in telecom projects. This choice hinges on understanding project-specific needs, environmental conditions, and capacity requirements. Whether a Vertical Splice Closure or a Horizontal Splice Closure, proper selection guarantees optimal performance.

Key Takeaways

- Choose between dome (vertical) or inline (horizontal) closures based on your project needs. Dome closures are good for underground use and offer more space. Inline closures are best for continuous fiber lines.

- Consider cable compatibility, environmental protection, and ease of installation. Make sure the closure fits your cables, can handle weather conditions, and is easy to work with.

- Plan for the future by picking a closure that can grow with your network. This saves money and effort later as your network expands.

Understanding Types of Fiber Optic Splice Closure

Dome (Vertical) Fiber Optic Splice Closure

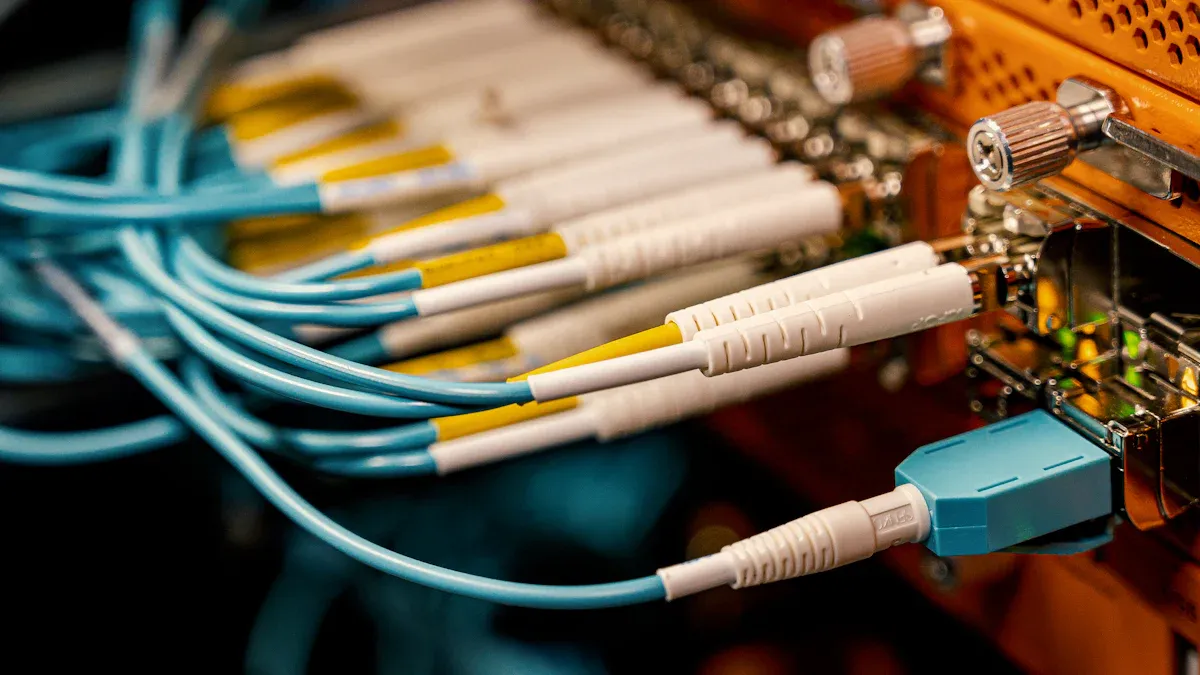

Dome (Vertical) Fiber Optic Splice Closures present a robust, dome-shaped design. This cylindrical structure offers excellent environmental protection. They often incorporate a clamp and O-ring system, ensuring secure sealing and water resistance. These closures also feature both mechanical and heat-shrinkable seals, which simplifies installation. Their design provides maximum internal space, making them easier to handle during splicing. Furthermore, they offer a safer method for storing slack, as cables typically enter from only one direction. Primarily designed for underground applications, these versatile closures also suit FTTX deployments. They support various topologies, including strand or pole mountings and below-grade vault placements. Their adaptability allows for aerial, pole, wall, or below-grade mounting, providing flexible placement options for a Fiber Optic Splice Closure.

Inline (Horizontal/Clamshell) Fiber Optic Splice Closure

Inline (Horizontal/Clamshell) Fiber Optic Splice Closures, also known as horizontal or clamshell closures, feature a slender, cylindrical, linear design. This design aligns with the cable path, making them ideal for continuous fiber runs. They facilitate straightforward in-line splicing and branching. These closures offer easy access and maintenance, typically including one or more fiber splicing trays. While fiber management can be more intricate due to cables entering from multiple directions, their structure provides versatility for various installations. These closures find common use in aerial, underground, and direct-buried applications. They are crucial for FTTH (Fiber to the Home) access networks and backbone networks, especially given their high fiber count and scalability. Industrial settings also benefit from inline closures, as they require resistance to mechanical impacts and harsh conditions.

Key Selection Criteria for a Fiber Optic Splice Closure

Choosing the correct Fiber Optic Splice Closure involves careful consideration of several critical factors. These elements ensure the closure meets the specific demands of a telecom project, guaranteeing network integrity and performance.

Cable Compatibility and Port Capacity

Project managers must first assess the types and quantities of cables a closure accommodates. Different closures support various cable diameters and fiber counts. Industry standards guide these compatibility requirements.

- IEC Standards (International Electrotechnical Commission):

- IEC 61753 defines performance requirements for fiber optic devices under various environmental conditions.

- IEC 61300 covers testing and measurement procedures for fiber optic interconnecting devices and passive components.

- TIA/EIA Standards (Telecommunications Industry Association/Electronic Industries Alliance):

- TIA/EIA-568 specifies standards for telecommunications cabling systems, including fiber optics.

- TIA/EIA-598 addresses fiber optic cable color coding, which is relevant for splicing.

- ISO Standards (International Organization for Standardization):

- ISO/IEC 11801 outlines general requirements for telecommunications cabling within specific premises types.

- EN Standards (European Norm):

- EN 50411 pertains specifically to fiber optic splice closures used with conduit and cable management systems.

- IP Rating (Ingress Protection):

- This rating determines the level of protection against solid objects, dust, accidental contact, and water for mechanical casings and enclosures.

- RoHS (Restriction of Hazardous Substances Directive):

- This directive is relevant for material safety, particularly in the European Union, by restricting hazardous materials in electrical and electronic products.

Modern closures offer impressive fiber capacities. A specific dome closure, for instance, handles up to 144 fibers. More advanced dome closures can accommodate up to 576 fibers, while horizontal closures typically manage up to 288 fibers. Dowell provides a range of closures designed for broad cable compatibility and high port capacity, meeting diverse project needs.

Environmental Protection and Sealing Mechanisms for Fiber Optic Splice Closure

The operational environment dictates the required level of protection. Closures must withstand moisture, dust, extreme temperatures, and UV radiation. Effective sealing mechanisms are crucial for preventing ingress.

A common and excellent IP rating for outdoor Fiber Optic Splice Closure is IP67. An IP67 rating signifies the enclosure is completely dust-tight. It also means the enclosure can be submerged in water up to 1 meter for 30 minutes. IP67 is considered a great all-around rating capable of withstanding most outdoor conditions.

Splice closures utilize sealing barriers to prevent water ingress, which can lead to signal attenuation and corrosion. They also incorporate sealed environments and filtration systems to block dust and particles, thereby maintaining reliable optical performance.

Effective sealing mechanisms include:

- Gaskets: These provide a compressible seal between mating surfaces.

- O-rings: These form a tight seal in grooves, preventing fluid or gas leakage.

| Sealing Mechanism | Description | Key Benefits |

|---|---|---|

| Heat-shrinkable | Material contracts when heated, creating a tight seal around cables. | Reliable, watertight, durable, resistant to harsh weather, easy installation, cost-effective. |

| Mechanical | Uses physical components like clamps or screws to secure the closure housing. | Forms a barrier against environmental factors, safeguards splices from external influences. |

Dowell’s closures feature advanced sealing technologies, ensuring maximum protection against environmental hazards.

Installation, Re-entry, and Maintenance of Fiber Optic Splice Closure

Ease of installation, re-entry, and maintenance significantly impacts project timelines and operational costs. A well-designed closure simplifies these processes.

Consider the recommended installation procedures for dome fiber optic splice closures:

- Splice fibers: Follow the user manual of the fusion splicing machine, paying attention to fiber twist and bend.

- Install heat shrinkable protective sleeve and house fibers: After splicing, house the first fiber ring on the farthest side of the FOST. Wind remaining fiber into a ring (diameter ≥ 80mm) and place it into the FOST with the heat shrinkable protective sleeve. Fix the sleeve into its slot and properly enlarge the fiber ring diameter. Pay attention to fiber twist and bend.

- Check up comprehensively: Ensure technical requirements are met by checking:

- Fibers with protective coats are fixed with nylon ties at the FOST entrance.

- Grommets are pressed from inside to outside for proper FOST installation.

- Straight-through and reserved fibers with protective coats are wound to the fiber holding tray.

- Internal tighteners and reinforced core fixing nuts are well tightened.

- Seal fitting is installed neatly and smoothly.

- Heat shrinkable fixing sleeve is reliable and completely sealed. Address any problems immediately.

- Assemble FOSC housing and fix FOSC: Place desiccant into the FOSC, then put the FOSC cover directly on the base. Install the plastic hoop between the cover and base, tighten the hoop locking system, and fix it with a hoop fixing bolt. For FOSC installation:

- Strand Overhead: Fasten steel wire with a metal clip.

- Pole application: Fix metal hoop and transom to the pole.

- Wall mounting: Fix the bracket on the wall with a bolt (metal hoop not required).

- Underground application: Metal hoop is not required. Pay attention during plastic hoop installation; the bracket bolt specification is M8.

Closures with tool-less entry, clear fiber routing, and modular components streamline field work. Dowell designs its closures for quick, efficient installation and hassle-free re-entry, minimizing downtime.

Scalability and Future-Proofing with Fiber Optic Splice Closure

Network demands evolve rapidly. A chosen closure should support future expansion without requiring complete replacement.

- Scalability for Future Growth: Fiber optic splice closures are designed to accommodate future network growth, allowing for the addition of new connections as demand for high-speed internet and data services increases. Their modular design enables easy expansion, ensuring communication systems can adapt to evolving technological needs.

- Easy Integration with Existing Infrastructure: These closures simplify the integration process into current systems, minimizing disruptions during upgrades or expansions. This user-friendly design ensures a seamless connection between new and existing components, supporting continuous network operation.

- Compatibility with Various Network Types: Fiber optic splice closures seamlessly integrate with different network types, including aerial, underground, and submarine networks. This adaptability allows for deployment in existing infrastructures without significant modifications, offering a cost-effective solution for enhancing network performance.

Recent advancements in closure design include:

- High-Density Splice Closure Development: Recent advancements include splice closures capable of handling a much higher number of fibers, accommodating denser fiber optic cables like ribbon fiber and microcubes. This allows network operators to maximize existing duct infrastructure, reduce the physical footprint of network equipment, and lower deployment costs by using fewer, higher-capacity closures.

- Emphasis on Tool-less and Quick Installation Designs: Innovations focus on optimizing splice closures for faster, easier, and often tool-free installation, incorporating features like one-piece gasket systems, snap-locking systems, and self-explanatory cable entry points. This accelerates fiber optic network rollouts, reduces field technician time and expertise, and lowers operational costs.

- Increasing Compatibility with Specialty Fiber Types: The market is seeing innovations in splice closures that are compatible with new and advanced fiber optic cable types, such as bend-insensitive fibers and microcubes. These closures are specifically designed to handle fragile fibers without signal loss, enabling the seamless incorporation of the latest fiber technologies into new or existing networks with optimal performance.

- Scalability and Modularity in Closure Designs: Recent advancements prioritize modular and scalable splice closure architecture, offering versatile configurations. Technicians can install or remove splice trays and cable entry ports as network demands change, providing network operators with greater flexibility for future growth and upgrades without needing to replace the entire closure, leading to more economical and future-proofed installations.

Dowell offers modular and scalable closures, providing the flexibility necessary for long-term network planning and upgrades.

Budget and Cost-Effectiveness of Fiber Optic Splice Closure

While initial purchase price is a factor, project managers must consider the total cost of ownership (TCO). This includes installation time, maintenance, and potential replacement costs.

Typical price ranges for high-capacity closures vary:

| Product Name | Splice Capacity (Single-Fusion) | Price |

|---|---|---|

| Commscope FOSC 450-D-D6V Dome Closure | 576 | $471.00 |

| Commscope FOSC 600-D Butt Closure | 864 | $650.00 |

| FIBER 3000 552-024 Aerial or Buried Fiber Optic Splice Closure | 24/48/96 | $149.00 |

| FIBER 3000 800-096 Horizontal Fiber Optic Splice Closure | 96 | $199.00 |

| Multilink 3000-F Starfighter Fiber Optic Splice Closure | High Capacity | $439.00 |

Pricing for fiber optic splice closures varies significantly across manufacturers due to differences in automation levels, material sourcing, and service models. While some Hangzhou-based manufacturers may offer lower base prices, they often come with higher Minimum Order Quantities (MOQs). In contrast, Shenzhen suppliers might have slightly higher unit costs but provide greater flexibility, faster turnaround, and superior service. Buyers are advised to consider the total cost of ownership (TCO), which includes not just the per-unit price but also logistics, inventory holding, and potential rework risks, rather than focusing solely on the initial purchase price.

| Supplier | Avg. Unit Price (USD) | MOQ (pcs) | Notable Strengths |

|---|---|---|---|

| Shenzhen Kexint Technology Co., Ltd. | $14.20 | 100 | 100% on-time delivery, strong after-sales |

| Hangzhou Photoelectric Technology Co., Ltd. | $12.80 | 500 | Lowest price tier, good for large orders |

| Ningbo Fibconet Communication Technology Co., Ltd. | $13.50 | 200 | Balanced pricing and fast response |

| Shenzhen Wirenet Telecom Technology Co., Ltd. | $14.00 | 100 | Excellent customization options |

| Hangzhou Softel Optic Co., Ltd. | $13.90 | 100 | Strong technical documentation |

Dowell offers competitive pricing without compromising on quality or performance, delivering excellent value and a lower TCO for telecom projects.

Matching Fiber Optic Splice Closure to Project Environments

Project environments significantly influence the choice of a Fiber Optic Splice Closure. Different settings demand specific features for optimal performance and longevity.

Aerial Applications for Fiber Optic Splice Closure

Aerial installations require closures to endure harsh outdoor conditions. These closures must withstand temperature fluctuations, humidity, vibration, and UV exposure. They need strong sealing, insulation, and resistance to alkali and salt corrosion. Materials must resist aging from UV radiation, rain, and snow, and endure repeated heating and cooling cycles without degradation. Temperature-resistant materials maintain stability from -45°C to +65°C. Hardware and accessories must also withstand wear and environmental stress. Common mounting methods include aerial and pole mounting, often utilizing robust mounting brackets to secure the closure.

Underground and Direct Buried Applications for Fiber Optic Splice Closure

Underground and direct buried applications demand highly sealed and rugged closures. These environments expose closures to moisture, soil pressure, and potential chemical exposure. Sealed dome closures, such as the AFL LG-250 and LG-350, are ideal for underground use where a completely sealed unit is necessary. The FIS Fiber Optic Splice Closure also offers a compact size and rugged design suitable for direct burial and below-grade deployments.

Wall-Mount and Pedestal Applications for Fiber Optic Splice Closure

Wall-mount closures are suitable for indoor environments, such as offices and small companies. They occupy less space, featuring shallow cases and hinged doors for easy access. This design allows neat organization of multiple fiber cables without extensive room. For outdoor residential areas, pedestal-mounted closures offer robust protection. They provide environmental protection with an IP68 rating, resisting dust and submersion up to 1.5 meters. These closures operate from -40°C to +80°C and feature strong ABS shells, steel locks, and thick walls for mechanical strength. Pedestals also simplify FTTx network rollouts, supporting widespread internet access by enabling easy integration into existing infrastructure.

A well-informed choice of Fiber Optic Splice Closure is fundamental for robust, efficient, and future-proof telecom networks. Project managers must consider all project specifics, environmental factors, and future needs for long-term network success. For reliable and high-quality Fiber Optic Splice Closures, explore solutions from Dowell: [https://www.fiberopticcn.com/about-us/]

FAQ

What distinguishes dome from inline fiber optic splice closures?

Dome closures offer a cylindrical design, providing maximum internal space and often suit underground applications. Inline closures feature a slender, linear design, ideal for continuous fiber runs and in-line splicing.

What IP rating should outdoor fiber optic splice closures have?

Outdoor fiber optic splice closures typically require an IP67 rating. This rating ensures complete dust-tightness and protection against water immersion up to 1 meter for 30 minutes, suitable for most outdoor conditions.

Why is scalability crucial for a fiber optic splice closure?

Scalability allows for future network expansion without replacing the entire closure. It supports increasing fiber counts and evolving network demands, ensuring long-term efficiency and cost-effectiveness for telecom projects.

Post time: Nov-20-2025