Efficient fiber optic investments depend on maximizing ROI, particularly with products like Fiber Optic Patch Cords. Businesses worldwide prioritize fiber optic networks due to their ability to deliver high-speed, reliable connectivity, including options such as the fiber optic patch cord sc/apc. Recent data highlights the global market’s robust growth, showcasing a CAGR that surpasses traditional broadband services. Investments in fiber optic infrastructure, including duplex fiber optic patch cords and armoured fiber optic patch cords, drive economic progress by enhancing business efficiency, attracting new industries, and creating jobs. Bulk purchasing of fiber optic patch cords offers a strategic pathway to amplify cost-efficiency and secure long-term benefits. By adopting this approach, organizations can streamline procurement, reduce operational costs, and ensure inventory readiness for future demands.

Key Takeaways

- Buying fiber optic cords in bulk saves money with discounts.

- Ordering in bulk makes buying faster, easier, and less mistake-prone.

- Keeping enough fiber optic parts ready helps avoid running out later.

- Using good-quality fiber optic parts makes networks work better and longer.

- Working with trusted sellers gives better prices and steady product quality.

Understanding Fiber Optic Patch Cords & Adapters

What Are Fiber Optic Patch Cords?

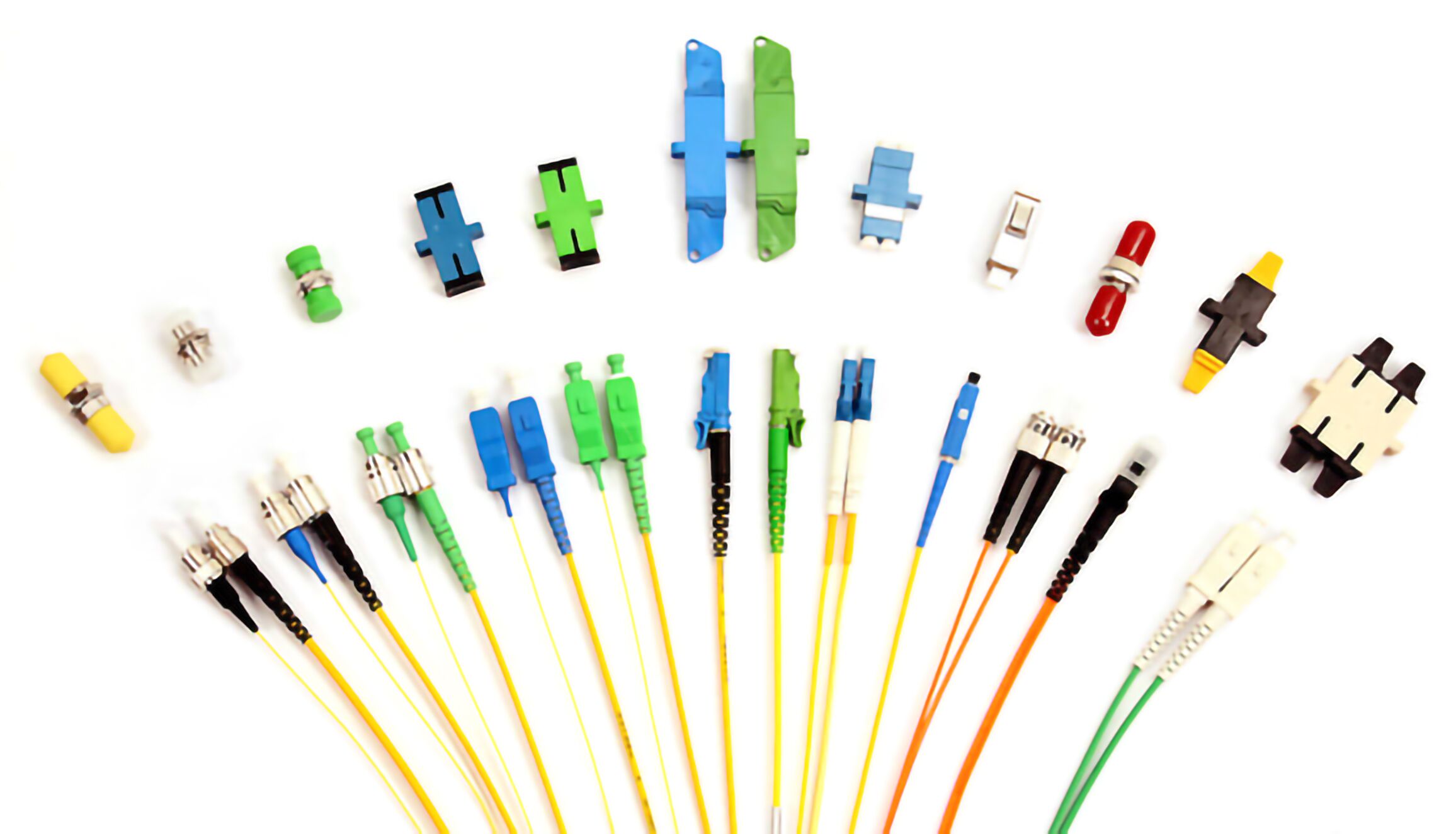

Fiber optic patch cords are essential components in modern communication networks. These cables connect devices within a fiber optic system, enabling the transmission of high-speed data. They consist of a fiber optic cable terminated with connectors on both ends, which allow seamless integration into network systems. Common connector types include SC, LC, and MPO, each designed for specific applications. According to industry standards like IEC 61280-1-4, these cords must meet strict performance criteria to ensure reliability and efficiency.

The fiber optic cable accessories market report highlights the growing demand for patch cords in data centers and telecommunications. This demand stems from the need for secure communication and high-speed data transmission, making patch cords indispensable in these industries.

The Role of Adapters in Fiber Optic Networks

Adapters play a critical role in connecting different types of fiber optic connectors. They act as bridges, ensuring compatibility between various connector types and enabling uninterrupted data flow. For instance, an SC-LC adapter allows seamless integration between SC and LC connectors. These components are vital in maintaining network flexibility and scalability.

Technical resources, such as articles and case studies, emphasize the importance of adapters in fiber optic networks. They showcase how adapters enhance system performance by reducing signal loss and ensuring stable connections. Reliable adapters contribute significantly to the overall efficiency of fiber optic systems.

Why High-Quality Components Matter for ROI

Investing in high-quality fiber optic components directly impacts ROI. Superior patch cords and adapters minimize network downtime, enhance data transmission speeds, and reduce maintenance costs. For example, a manufacturing company that upgraded to high-quality fiber optic systems reported a 76% increase in productivity and a 50% reduction in downtime. These improvements translate into substantial cost savings and operational efficiency.

High-quality components also comply with industry standards, ensuring long-term reliability. Businesses that prioritize quality in their fiber optic investments position themselves for sustained growth and profitability.

The ROI Benefits of Bulk Purchasing

Cost Savings Through Volume Discounts

Bulk purchasing offers significant financial advantages for organizations investing in fiber optic infrastructure. Suppliers often provide volume discounts, reducing the cost per unit when purchasing large quantities of Fiber Optic Patch Cords. This approach not only minimizes upfront expenses but also ensures a steady supply of essential components for future projects. For example, companies procuring fiber optic transceivers in bulk have reported substantial cost reductions, enabling more effective budget allocation for large-scale operations. These savings directly contribute to a higher return on investment (ROI), making bulk purchasing a strategic choice for businesses aiming to optimize their resources.

Tip: Collaborating with suppliers like Dowell can help businesses secure competitive pricing and maintain a consistent inventory of high-quality Fiber Optic Patch Cords.

Streamlining Procurement Processes

Bulk purchasing simplifies procurement workflows, leading to improved efficiency and reduced operational costs. Organizations benefit from streamlined purchase order flows, which integrate seamlessly with enterprise resource planning (ERP) systems. This automation minimizes manual intervention, reducing the likelihood of human error. Key performance indicators (KPIs) such as cost reduction and procurement effectiveness highlight the advantages of bulk purchasing.

- Automated purchase order creation shortens processing times.

- Enhanced visibility and traceability improve financial forecasting.

- Consolidated orders reduce administrative overhead.

By adopting bulk purchasing strategies, businesses can focus on core operations while ensuring their procurement processes remain efficient and cost-effective.

Inventory Management for Long-Term Efficiency

Effective inventory management is crucial for maintaining operational continuity in fiber optic networks. Bulk purchasing allows organizations to stockpile essential components like Fiber Optic Patch Cords, ensuring readiness for future demands. This approach reduces the risk of supply chain disruptions and eliminates the need for frequent reordering. Companies can also leverage inventory tracking systems to monitor stock levels and prevent overstocking.

Maintaining an optimal inventory of high-quality components enhances network reliability and minimizes downtime. Businesses that prioritize inventory efficiency position themselves for sustained growth and operational success.

Strategies for Bulk Purchasing Fiber Optic Patch Cords

Evaluating Current and Future Business Needs

Organizations must assess their current and anticipated requirements before committing to bulk purchases of Fiber Optic Patch Cords. This evaluation ensures that procurement aligns with operational goals and avoids unnecessary expenditures. Businesses should analyze their network infrastructure, considering factors such as bandwidth demands, scalability, and compatibility with existing systems. For instance, a company planning to expand its data center operations may require higher quantities of duplex or armored patch cords to support increased connectivity.

Forecasting future needs is equally important. Companies should account for industry trends, technological advancements, and potential business growth. By doing so, they can avoid underestimating their requirements, which could lead to supply shortages. Tools like demand forecasting software and historical usage data can provide valuable insights, enabling organizations to make informed purchasing decisions.

Tip: Collaborating with experienced suppliers like Dowell can help businesses accurately assess their needs and ensure they procure the right type and quantity of Fiber Optic Patch Cords.

Ensuring Quality and Industry Standards

High-quality components are essential for maintaining the performance and reliability of fiber optic networks. Organizations should prioritize products that meet established industry standards to ensure long-term efficiency and ROI. Several certifications and audits verify the quality of fiber optic components:

- IEC Standards: Focus on performance and safety parameters, including dimensions and mechanical properties.

- TIA Standards: Provide guidelines for interoperability and performance in telecommunications.

- ISO Standards: Emphasize quality management systems, ensuring consistent product quality.

- Verizon Certified ITL Program: Audits management requirements, quality systems, and technical specifications to ensure compliance with Telcordia Generic Requirements (GRs).

These certifications demonstrate a supplier’s commitment to quality and adherence to industry benchmarks. Businesses should request documentation of compliance when evaluating potential suppliers. Additionally, conducting performance tests on sample products can help verify their reliability and suitability for specific applications.

Selecting Reliable Suppliers

Choosing the right supplier is critical for successful bulk purchasing. Reliable suppliers ensure consistent product quality, timely delivery, and competitive pricing. Organizations should evaluate suppliers using established frameworks and performance metrics. Key evaluation methods include:

| Evaluation Type | Description |

|---|---|

| Performance Testing Services | Assess fiber-optic products for performance and reliability against standards. |

| Supplier Evaluation Frameworks | Frameworks like balanced scorecards evaluate suppliers on multiple dimensions. |

| Key Performance Indicators (KPIs) | Metrics such as On-Time Delivery, Quality Defect Rate, Lead Time, and Cost Competitiveness. |

- On-Time Delivery (OTD): Measures the percentage of orders delivered on schedule.

- Quality Defect Rate: Indicates the frequency of defective products received.

- Lead Time: Tracks the time taken from order placement to delivery.

- Cost Competitiveness: Compares supplier prices with market rates.

Building strong relationships with suppliers like Dowell can further enhance procurement efficiency. Long-term partnerships often lead to better pricing, priority service, and access to new product innovations. Businesses should also consider suppliers with a proven track record in the fiber optic industry to minimize risks and ensure consistent performance.

Negotiating Favorable Terms and Discounts

Negotiating favorable terms with suppliers is a critical step in maximizing ROI when purchasing Fiber Optic Patch Cords in bulk. Businesses can achieve significant cost savings by leveraging their purchasing power and establishing mutually beneficial agreements. Effective negotiation strategies include:

- Volume-Based Discounts: Suppliers often provide reduced pricing for larger orders. Businesses should calculate their long-term needs and negotiate discounts based on projected volumes.

- Flexible Payment Terms: Negotiating extended payment periods or installment options can improve cash flow management.

- Incentives for Long-Term Contracts: Suppliers may offer additional discounts or benefits for multi-year agreements, ensuring price stability and consistent supply.

Tip: Collaborating with suppliers like Dowell can help businesses secure competitive pricing while maintaining high-quality standards.

Clear communication and preparation are essential for successful negotiations. Businesses should research market prices, understand supplier capabilities, and outline their requirements before entering discussions. This approach ensures that both parties achieve a win-win outcome, fostering a strong foundation for future collaboration.

Using Technology to Optimize Procurement

Technology plays a pivotal role in streamlining procurement processes for Fiber Optic Patch Cords. Advanced tools and platforms enable businesses to automate workflows, enhance decision-making, and reduce operational inefficiencies. Key technologies include:

- Procurement Software: Platforms like ERP systems integrate purchasing, inventory management, and financial planning, providing a centralized solution for procurement activities.

- Data Analytics: Analyzing historical purchasing data helps businesses identify trends, forecast demand, and optimize order quantities.

- Supplier Portals: Online portals facilitate real-time communication, order tracking, and performance monitoring, ensuring transparency and accountability.

For example, a company using procurement software reported a 30% reduction in processing times and a 20% decrease in procurement costs. These tools also improve accuracy by minimizing manual errors, ensuring that businesses maintain a steady supply of essential components without overstocking.

Note: Investing in technology not only enhances procurement efficiency but also positions businesses for scalability and growth in a competitive market.

Building Strong Supplier Relationships

Strong supplier relationships are the cornerstone of successful bulk purchasing strategies. Businesses that prioritize collaboration and trust with their suppliers gain access to numerous benefits, including improved efficiency, cost savings, and innovation. The following table highlights the advantages of robust supplier partnerships:

| Benefit | Description |

|---|---|

| Improved Efficiency and Cost Reduction | Streamlined processes, reduced errors, and better communication lead to significant cost savings. |

| Enhanced Visibility and Risk Management | Real-time insights allow for proactive risk management, minimizing disruptions. |

| Increased Innovation and Product Development | Strong partnerships foster collaboration and knowledge sharing, leading to faster product development. |

| Greater Agility and Responsiveness | A streamlined supply chain allows quick adaptation to market demands. |

| Improved Brand Reputation and Customer Satisfaction | Consistent on-time delivery and high-quality products enhance brand reputation. |

To build and maintain strong supplier relationships, businesses should adopt the following strategies:

- Regular Communication: Frequent updates and meetings ensure alignment on goals and expectations.

- Joint Planning Sessions: Collaborative planning fosters mutual understanding and shared success.

- Long-Term Contracts: Multi-year agreements demonstrate commitment and encourage suppliers to prioritize quality and service.

Tip: Partnering with experienced suppliers like Dowell ensures reliability, quality, and potential cost savings, creating a foundation for long-term success.

Overcoming Challenges in Bulk Purchasing

Managing Overstocking Risks

Overstocking can lead to increased storage costs, tied-up capital, and wasted resources. Businesses must adopt proactive strategies to mitigate these risks and optimize inventory management. Several approaches have proven effective in addressing overstocking challenges:

- Adopt lean principles to eliminate waste and maximize value in supply chain processes.

- Conduct regular reviews to assess efficiency and identify bottlenecks.

- Integrate sustainability goals to align with customer expectations and reduce environmental impact.

- Implement Just-In-Time (JIT) inventory management to maintain only necessary stock levels, reducing holding costs while preparing for potential disruptions.

- Prioritize critical stock to ensure essential items remain available during demand fluctuations.

- Track inventory with RFID technology for accurate monitoring and proactive adjustments.

By combining these strategies, businesses can balance inventory levels, reduce costs, and maintain operational efficiency. Strong vendor relationships further enhance this process, ensuring reliable supply chains and minimizing risks.

Ensuring Compatibility with Existing Systems

Compatibility issues can disrupt network performance and delay project timelines. Businesses must prioritize thorough testing and integration to ensure new fiber optic components align with existing systems. Real-world examples highlight the importance of compatibility:

- A financial services firm implemented CWDM technology to enhance data transmission, achieving higher bandwidth and reduced latency for real-time transactions.

- An educational institution upgraded to DWDM technology to alleviate network congestion, enabling high-speed connectivity for e-learning and research.

- A healthcare network utilized fiber multiplexers to improve data transfer between facilities, enhancing telehealth services and maintaining patient care standards.

These cases demonstrate the value of compatibility testing and strategic upgrades. Businesses should collaborate with suppliers to verify product specifications and conduct integration trials before deployment. This approach ensures seamless operations and maximizes ROI.

Mitigating Supplier Reliability Issues

Supplier reliability directly impacts procurement success and operational continuity. Businesses must adopt measures to mitigate risks and ensure consistent performance. Key strategies include:

- Evaluate supplier track records using metrics like on-time delivery rates and defect percentages.

- Diversify supplier networks to reduce dependency on a single source.

- Establish long-term contracts to foster trust and prioritize quality.

- Monitor supplier performance through regular audits and feedback sessions.

Building strong relationships with suppliers like Dowell ensures access to high-quality components and reliable service. Proactive communication and collaboration further strengthen these partnerships, enabling businesses to navigate challenges effectively and maintain supply chain stability.

Future Trends in Fiber Optic Procurement

Sustainable Sourcing Practices

Sustainability has become a cornerstone of modern procurement strategies, including in the fiber optics industry. Companies increasingly prioritize environmentally responsible practices to align with global ESG (Environmental, Social, and Governance) standards. For instance:

- 98% of S&P 500 companies published ESG reports in 2022, reflecting the growing emphasis on sustainability.

- Lumen Technologies achieved a 25% reduction in Scope 1 and Scope 2 emissions since 2018, showcasing their commitment to reducing environmental impact.

- Major service providers like AT&T conduct climate change risk assessments to ensure sustainable operations.

These efforts highlight the industry’s shift toward eco-friendly sourcing, which not only reduces carbon footprints but also enhances brand reputation. Businesses adopting sustainable practices position themselves as leaders in a competitive market while meeting the increasing demand for green solutions.

Innovations in Fiber Optic Technology

Technological advancements continue to revolutionize fiber optic procurement and deployment. Recent innovations include:

| Advancement Type | Description |

|---|---|

| Bend-Insensitive Fibers | Engineered to withstand tight curves, enhancing flexibility and installation convenience. |

| Automated Deployment Technologies | Includes robotic cable laying and drone-assisted techniques, reducing installation time and costs. |

| Power over Ethernet (PoE) | Combines data and power transmission, improving reliability and sustainability in fiber networks. |

| IoT Integration | Fiber networks support the scalability and connectivity needed for the growing number of IoT devices. |

| Future Services | High-speed internet and technologies like AR and VR are facilitated by advanced fiber networks. |

These innovations address the growing demand for high-speed internet, driven by the expansion of 5G networks, data centers, and cloud infrastructure. Businesses leveraging these technologies can enhance operational efficiency and meet evolving customer needs.

Automation and AI in Procurement Processes

Automation and AI are transforming procurement processes, making them faster and more efficient. AI-powered systems streamline fiber optic testing, reducing errors and expediting timelines. Key benefits include:

- Automated testing systems improve accuracy and efficiency compared to traditional methods.

- AI reduces manual design timelines from 45-60 days to approximately 25 days, accelerating procurement cycles.

- Algorithms optimize bandwidth management by dynamically adjusting resources based on usage patterns.

These advancements enable businesses to reduce costs, improve decision-making, and maintain a competitive edge. By integrating AI and automation, organizations can future-proof their procurement strategies and adapt to the rapidly evolving fiber optics landscape.

Strategic bulk purchasing of fiber optic patch cords and adapters offers businesses a clear pathway to maximize ROI. By leveraging volume discounts, companies can achieve significant cost reductions, as shown below:

| Product Category | Price Reduction (%) |

|---|---|

| Optical Fiber Cables | 10% to 20% |

| Optical Modules | 15% to 30% |

| Transceivers | 20% to 40% |

Beyond financial savings, bulk purchasing streamlines procurement processes and ensures inventory readiness, enhancing operational efficiency. Organizations that adopt these strategies position themselves for long-term success. Taking proactive steps, such as partnering with reliable suppliers like Dowell, ensures access to high-quality components and consistent support. Businesses should act now to secure these advantages and drive sustainable growth.

FAQ

What are the key benefits of bulk purchasing fiber optic patch cords?

Bulk purchasing reduces costs through volume discounts and ensures a steady supply of essential components. It streamlines procurement processes, minimizes administrative overhead, and supports long-term inventory management. These advantages contribute to higher ROI and operational efficiency.

How can businesses ensure the quality of fiber optic components?

Organizations should prioritize suppliers that comply with industry standards like IEC and TIA. Requesting certifications, conducting performance tests, and reviewing supplier track records ensure the quality and reliability of fiber optic components.

Tip: Partnering with trusted suppliers like Dowell guarantees access to high-quality products.

What factors should businesses consider when selecting a supplier?

Key factors include product quality, on-time delivery rates, pricing competitiveness, and supplier reliability. Evaluating these metrics ensures consistent performance and minimizes risks in procurement.

How does technology optimize the procurement process?

Procurement software and data analytics streamline workflows, improve decision-making, and reduce errors. These tools enable businesses to forecast demand, track inventory, and maintain efficient supply chains.

How can businesses avoid overstocking when purchasing in bulk?

Effective inventory management strategies, such as Just-In-Time (JIT) systems and demand forecasting, help prevent overstocking. Regular inventory reviews and RFID tracking also ensure optimal stock levels.

Note: Collaborating with experienced suppliers like Dowell can further reduce risks and enhance inventory efficiency.

Post time: Apr-29-2025