EU standards govern fiber optic cables for pan-European projects. Compliance is critical for successful deployment. The Europe fiber optics market was estimated at USD 2.0 billion in 2023, reaching USD 2,103.4 million in 2024, highlighting the industry’s significant scale. Project managers ensure the selection and implementation of compliant Fiber Optic Cable through careful vetting.

Key Takeaways

- Following EU rules for fiber optic cables is very important for projects across Europe. This helps avoid big fines and keeps projects running smoothly.

- Key EU rules like CPR, RoHS, and REACH make sure fiber optic cables are safe, do not harm the environment, and work well. These rules cover fire safety, harmful materials, and chemical use.

- Choosing the right cable maker and keeping good records are key steps to meet EU standards. This ensures your fiber optic cables are reliable and safe for everyone.

Understanding the EU Regulatory Landscape for Fiber Optic Cables

Risks of Non-Compliance for Fiber Optic Cable Projects

Non-compliance with EU standards carries significant risks for fiber optic cable projects. Companies face substantial financial penalties and legal repercussions. Authorities can impose fines, and projects may experience delays or even complete halts. This also damages a company’s reputation and trustworthiness within the industry. Furthermore, non-compliant cables may pose safety hazards, compromising the integrity and reliability of the entire network infrastructure. Such issues can lead to costly rework and operational disruptions.

Key EU Directives and Regulations Impacting Fiber Optic Cables

Several key EU directives directly impact the manufacturing and deployment of fiber optic cables. The Low Voltage Directive (LVD) ensures high safety and performance standards for optical fiber composite low-voltage insulated power cables. The Electromagnetic Compatibility Directive (EMC) also ensures high safety and performance standards for these cables, with recent updates emphasizing resilience against electromagnetic interference. Additionally, the General Data Protection Regulation (GDPR) influences data handling practices within fiber-optic infrastructure, particularly for smart metering and IoT-enabled systems. These directives establish fundamental requirements for products placed on the EU market.

The Role of Harmonized Standards for Fiber Optic Cables

Harmonized standards play a crucial role in demonstrating compliance with EU directives. These are European standards developed by recognized European Standards Organizations. They provide detailed technical specifications for products, services, or processes. Manufacturers who follow harmonized standards can presume their products comply with the essential requirements of relevant EU legislation. This simplifies the compliance process and facilitates market access across the EU. They offer a clear path for manufacturers to meet regulatory obligations efficiently.

Core EU Standards for Fiber Optic Cable Performance and Safety

Construction Products Regulation (CPR) for Fiber Optic Cables: Fire Performance

The Construction Products Regulation (CPR) significantly impacts fiber optic cables used in buildings and civil engineering works. This regulation ensures safety and performance for construction products across the European Union. CPR primarily focuses on the reaction to fire performance of cables, including fiber optic cables. It aims to limit the production and spread of flame and smoke during a fire. The regulation mandates the declaration of fire performance and CE marking for cables installed in structures.

The CPR specifies requirements for the reaction to fire performance of ‘power, control, and communication’ cables, including fiber optic cables, used in any structure. It focuses solely on ‘reaction to fire’ performance. Future standards will address ‘resistance to fire’ performance (circuit integrity). The regulation also mandates CE marking and specifies how manufacturers should prepare fire performance declarations.

Under CPR EN 50575, fiber optic cables fall under specific fire performance classes. The Euroclass System provides a common technical language across Europe for reaction to fire requirements. This system ranges from Aca (non-combustible) to Fca (flammable). Manufacturers also classify cables based on smoke production (s1, s2, s3), which considers smoke opacity and visibility during evacuation. Flaming droplets classification (d0, d1, d2) accounts for burning droplets that can ignite other materials. Finally, the acidity/toxicity of smoke (a1, a2, a3) provides information on the corrosive properties and toxicity of released gases.

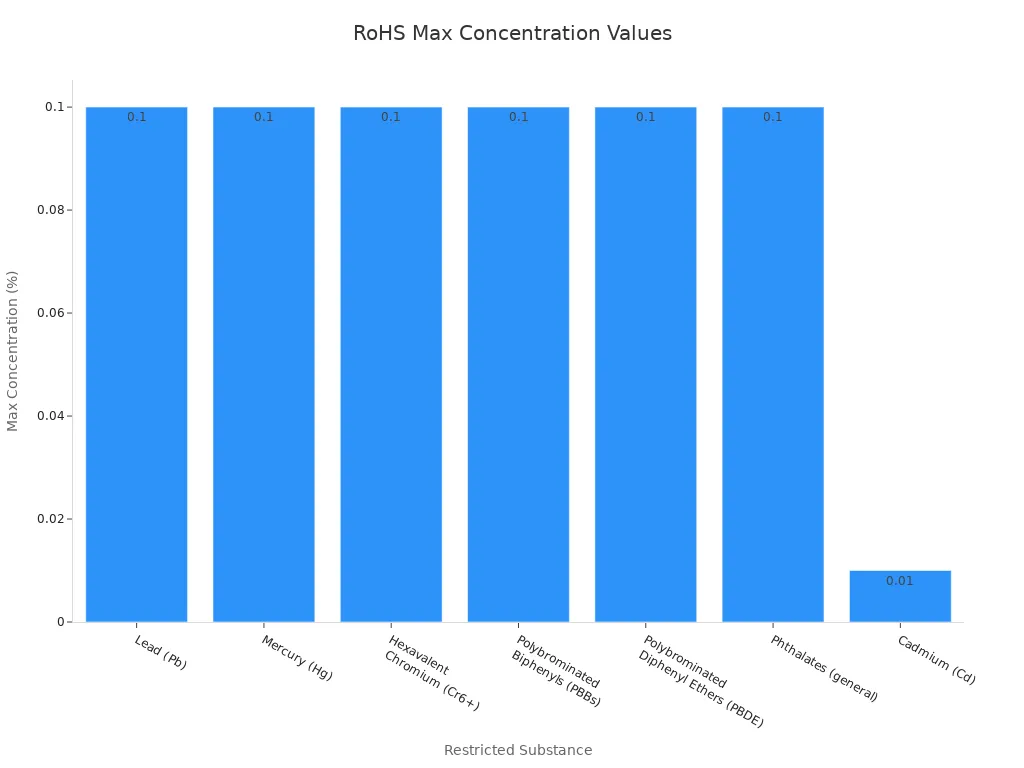

Restriction of Hazardous Substances (RoHS) Directive for Fiber Optic Cable Materials

The Restriction of Hazardous Substances (RoHS) Directive limits the use of specific hazardous materials in electrical and electronic products. This directive aims to protect human health and the environment. It applies to IT and telecommunication equipment, which includes raw materials for fiber optics manufacturing.

The RoHS directive restricts the use of several hazardous substances. These include:

- Lead

- Mercury

- Cadmium

- Hexavalent chromium

- Polybrominated biphenyls (PBB)

- Polybrominated diphenyl ether (PBDE)

Manufacturers must ensure their products do not exceed maximum concentration values for these restricted substances. The table below shows these limits:

| Substance | Maximum Concentration Value (by weight) |

|---|---|

| Cadmium (Cd) | < 0.01% (100 ppm) |

| Lead (Pb) | < 0.1% (1000 ppm) |

| Mercury (Hg) | < 0.1% (1000 ppm) |

| Hexavalent Chromium (Cr VI) | < 0.1% (1000 ppm) |

| Polybrominated Biphenyls (PBB) | < 0.1% (1000 ppm) |

| Polybrominated Diphenyl Ethers (PBDE) | < 0.1% (1000 ppm) |

| Bis(2-ethylhexyl) phthalate (DEHP) | < 0.1% (1000 ppm) |

| Benzyl butyl phthalate (BBP) | < 0.1% (1000 ppm) |

| Dibutyl phthalate (DBP) | < 0.1% (1000 ppm) |

| Diisobutyl phthalate (DIBP) | < 0.1% (1000 ppm) |

Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) Regulation for Fiber Optic Cables

The REACH Regulation (EC 1907/2006) protects human health and the environment. It also promotes competitiveness and innovation within the chemical industry. This regulation governs the Registration, Evaluation, Authorization, and Restriction of Chemical substances. It applies to all chemical substances and affects most companies within the EU.

REACH mandates that manufacturers and importers declare the presence of Substances of Very High Concern (SVHC) if they exceed 0.1% weight by weight in all articles. This includes specific substances found in fiber optic cable components. For example, Decabromodiphenyl ethane (DBDPE), a flame retardant, has been added to the SVHC list. It is present in fiber optics, directly affecting manufacturers who use it. The regulation aims to enhance the protection of human health and the environment. It establishes procedures for assessing and managing chemical hazards.

Any company manufacturing or shipping articles into the EU must document any use of SVHCs above 0.1% under the REACH Regulation. A supplier of a product containing an SVHC from the candidate list in a concentration greater than 0.1% (w/w) must inform its consumers. This notification must include at least the name of the substance. Companies like Habia Cable, which produce wires, cables, and cable systems (articles), identify themselves as downstream users. They do not have an obligation to register their products. However, if they import substances from outside the EU, they must ensure registration occurs if applicable.

Waste Electrical and Electronic Equipment (WEEE) Directive: End-of-Life Management for Fiber Optic Cables

The Waste Electrical and Electronic Equipment (WEEE) Directive addresses the environmental impact of electronic waste. It promotes the collection, recycling, and recovery of electrical and electronic equipment. This directive aims to reduce the amount of waste sent to landfills and encourages the reuse of materials.

While fiber optic cables themselves are not always classified as “electrical and electronic equipment” in the same way as a computer, the WEEE Directive still influences their end-of-life management. The directive covers the equipment that uses these cables, such as network devices and telecommunication infrastructure. Manufacturers and distributors of such equipment must ensure proper disposal and recycling. This indirectly impacts the overall sustainability practices surrounding fiber optic cable deployments. Companies must consider the entire lifecycle of their products, including how they will be managed once they are no longer in use.

Technical Specifications and Performance Standards for Fiber Optic Cables

Project success in pan-European deployments relies on adherence to precise technical specifications and performance standards. These standards ensure interoperability, reliability, and optimal network performance across diverse environments.

Optical Performance Standards for Fiber Optic Cables (ITU-T G.65x series)

The International Telecommunication Union – Telecommunication Standardization Sector (ITU-T) G.65x series defines critical optical performance characteristics for single-mode optical fibers. These standards ensure fibers meet specific transmission requirements. For instance, G.652 is the standard single-mode fiber, with variants like G.652.D eliminating the water peak for full spectrum operation. G.657, on the other hand, specifies bend-insensitive fibers crucial for installations in confined spaces.

| Standard | Key Feature | Best For |

|---|---|---|

| G.652 (Standard SMF) | Low-water-peak (G.652D) for full spectrum use (1310 nm to 1550 nm), suitable for CWDM. | Long-haul, metro, and access network backbones; reliable, long-distance transmission where extreme bending is not a primary concern. |

| G.657 (Bend-Insensitive Fiber) | Extremely low macro-bending loss (e.g., G.657.A2 with 7.5 mm bend radius). | Fiber-to-the-Home (FTTH), data centers, and dense enterprise environments; installations in confined spaces. |

| G.655 (Non-Zero Dispersion-Shifted Fiber) | Shifts zero-dispersion point outside 1550 nm to suppress Four-Wave Mixing (FWM) in DWDM systems while maintaining low chromatic dispersion. | High-capacity Dense Wavelength Division Multiplexing (DWDM) systems. |

ITU-T G.652.D specifies key optical parameters for standard single-mode fiber optic cable, ensuring consistent performance.

| Parameter | Value |

|---|---|

| Attenuation (1310 to 1625nm) | ≤ 0.4 dB/km |

| Attenuation (1550nm) | ≤ 0.3 dB/km |

| Macrobending Loss (1625nm) | ≤ 0.5 dB |

| PMD | ≤ 0.2 ps/sqrt(km) |

Mechanical and Environmental Performance of Fiber Optic Cables (IEC 60794 series)

The International Electrotechnical Commission (IEC) 60794 series outlines test methods for the mechanical and environmental performance of fiber optic cables. IEC 60794-1-1:2023 serves as a generic specification. It establishes uniform requirements for various properties, including mechanical and aging properties. This document acts as the default reference for all other parts of the IEC 60794-x series. It ensures cables withstand installation stresses and environmental conditions. For example, outdoor cables require specific tensile strength and crush resistance.

| Characteristic | Value |

|---|---|

| Tensile strength (short-term) | 2700–20000 N |

| Crush resistance | 2000–5000 N/100 mm |

| Direct-buried cable crush resistance | 3000 N/100 mm |

Specific Standards for Different Fiber Optic Cable Types

Different applications demand specific cable types, each with its own set of standards. Indoor cables, for instance, prioritize fire safety and flexibility. Outdoor cables focus on durability against environmental factors like moisture, temperature extremes, and rodent protection. Submarine cables require extreme robustness for underwater deployment. Adhering to these specific standards ensures the chosen cable type performs optimally for its intended use.

Achieving and Demonstrating Compliance for Fiber Optic Cables

Selecting Compliant Fiber Optic Cable Manufacturers

Selecting the right manufacturer is a critical first step in ensuring compliance for fiber optic cable projects. Project managers must evaluate potential suppliers based on stringent criteria to guarantee product quality and regulatory adherence. Manufacturers should demonstrate commitment to quality management through certifications like ISO 9001. This certification verifies consistent processes, reduces production variability, and ensures proper record-keeping. Furthermore, adherence to IEC 60794 standards for fiber construction and RoHS for material safety is essential. Verifying these certifications, along with manufacturer test reports such as OTDR traces and insertion-loss values, ensures consistent quality and performance. Lot traceability also confirms that delivered reels match factory test results.

| Certification / Standard | What it verifies | Why it matters |

|---|---|---|

| ISO 9001 | Consistent quality management processes | Reduces production variability and preserves records |

| IEC 60794 (fiber specs) | Mechanical and optical construction standards | Ensures fiber meets loss, strength, and environmental specifications |

| RoHS | Limits hazardous substances in materials | Supports regulatory compliance and on-site safety |

| Manufacturer lot traceability | Batch-level test and trace records | Confirms delivered reels match factory test results |

Manufacturers must also provide detailed attenuation and insertion loss data, which are crucial for accurate link budget calculations. They should supply OTDR traces and per-connector loss reports, along with documented test methods and calibration records. Beyond these, look for vendors with experience in relevant sectors, such as data centers or healthcare. This experience indicates familiarity with specific requirements like redundancy and bend-radius control. Reviewing past projects, technician certifications, and their on-site QA and safety protocols provides further assurance.

Strong project management capabilities are equally important. These capabilities ensure installations stay on schedule and within budget. Key deliverables to request include site surveys, detailed schedules, QA checkpoints (splice logs, insertion-loss reports), and as-built drawings. Clear change control and communication are also vital for successful project execution.

Finally, assess the manufacturer’s service and support offerings. Evaluate warranty terms for both materials and workmanship. Consider maintenance contracts with defined response times (Service Level Agreements or SLAs) and emergency repair services. Proactive maintenance, spare inventory management, and thorough documentation contribute to a lower total cost of ownership and reduced downtime. Responsive customer service, characterized by dedicated account managers, documented response SLAs, and regular status reporting, streamlines procurement and issue resolution. A supplier’s local presence and adherence to regional codes affect permitting, crew availability, and liability. Verify local licensing, insurance, and familiarity with regional inspection cadences to ensure smooth project execution and compliance.

| Service Type | Typical deliverable / SLA | Benefit to client |

|---|---|---|

| Materials warranty | Manufacturer coverage for defects | Protects the capital investment in cabling |

| Workmanship warranty | Installer repair/replace for installation faults | Ensures splices and terminations meet specifications |

| Emergency repair SLA | Committed response time (hours) | Reduces Mean Time To Repair (MTTR) and downtime costs |

| Maintenance contract | Scheduled inspections and condition reports | Preserves performance and spots issues early |

Manufacturers should possess various certifications and accreditations to demonstrate compliance. These include:

- IEC 60794: Requirements for optical fiber and cable elements for indoor and outdoor applications.

- Telcordia GR-20: Compliance for generic requirements and characteristics of single-mode and multimode optical fibers, ribbons, and cables for Outside Plant (OSP) use.

- ICEA S-87-640: Standard for Optical Fiber Outside Plant Communications Cable.

- ICEA S-110-717: Standard for Optical Fiber Drop Cable.

- UL 94 Certification: Underwriters Laboratories Standard 94 Certification on Fiber Optic Connectors and Attenuators for flammability of plastic materials.

- Telcordia GR-326, 3120, 1081, 910, 1209, 1221: Applicable to Fiber Optic Connectors, Attenuators, Jumpers, and Pigtails.

- TIA FOCIS-3: Compliance for Type SC and SC-APC Connector Intermateability.

- RoHS: Compliance with the Restriction of Hazardous Substances directive.

- IP68 grading: For Fiber Optic Closures, ensuring full protection against dust and complete immersion in water.

- IEEE 1591.2-2017: Standard for overhead aerial fiber optic cable installations, covering functional, electrical, mechanical, and other requirements.

Essential Documentation for Fiber Optic Cable Compliance

Proper documentation is indispensable for demonstrating compliance throughout a project’s lifecycle. The Declaration of Performance (DoP) is a required document that details the cable’s performance characteristics. CE marking, another crucial certification, indicates compliance with European safety standards.

Additional key documents and tools related to CPR compliance include:

- CPR Application Form for Cables

- System 1+ Certification Flowchart

- Sample DoP Template

- FPC Documentation Checklist

These documents collectively provide a comprehensive record of a product’s adherence to regulatory requirements.

Understanding CE Marking for Fiber Optic Cables

The CE marking on fiber optic cables serves as a ‘passport’ for products to be sold in the European market. It signifies that the product meets the basic safety requirements of the EU, particularly concerning the safety of human beings, animals, and goods, rather than general quality. It is a compulsory safety certification mark, indicating conformity with EU directives on technical coordination and standardization, allowing free circulation within EU member states.

The CE mark on fiber optic cables specifically indicates compliance with EU health, safety, and environmental requirements, particularly under the Construction Products Regulation (CPR). This mark must be backed by a full Declaration of Performance (DoP) and correct testing. A compliant CE label for cables includes:

- The CE symbol

- Notified Body number

- Reference to the DoP

- Euroclass classification (e.g., Cca s1b d0 a1)

- Harmonized standard (EN 50575:2014+A1:2016)

Since 2017, all cables under the purview of EN 50575 are mandated to have CPR certification before being sold in the EU market, with a key focus on their fire reaction efficiency. The implementation of CPR, which the CE mark signifies compliance with, aims to achieve several safety and well-being objectives in the construction industry. These objectives include limiting flame spread and emissions of noxious fumes from building elements, recapturing the stability of buildings in regard to disasters, and encouraging construction plans that utilize energy conservation abilities. Other goals involve decreasing poisonous materials release or drainage, fostering intelligent design and refurbishing of used furniture, and ensuring proper exit and accessibility facilities in public buildings. The decisive aspect for cables, directly related to CE marking, is their fire reaction efficiency.

Several standards underpin the CE marking for cables:

| Standard | Purpose |

|---|---|

| EN 50575 | Core regulation for cables subject to fire reaction requirements |

| EN 50399 | Measures heat release and smoke production during flame spread |

| EN 60332-1-2 | Tests vertical flame propagation (does fire travel up the cable?) |

| EN 61034-2 | Quantifies smoke density — critical for visibility during evacuation |

| EN 60754-2 | Assesses acidity of gases released — high acidity damages equipment and lungs |

| EN ISO 1716 | Determines calorific value (how much energy the material releases when burned) |

Applying the CE marking to cables involves a structured process:

- Testing: All manufacturers must test their products according to the CPR and the cable standard EN 50575. An authorized body or laboratory must perform testing. Key criteria include flame propagation and heat release (EN 60332-1-2 and EN 50399), with additional criteria for smoke opacity, droplet fall during combustion, and smoke acidity for higher classes.

- Classification: After testing, products are classified based on Euro classes (Aca, B1ca, B2ca, Cca, Dca, Eca, Fca). These classes define the ‘Reaction to Fire’ performance. Manufacturers receive a certificate of conformity to the applicable Euro class.

- Labeling: CE marking is mandatory and must be present on the product label (reel) and packaging. The label must include the Declaration of Performance (DoP) number, the Declared Performance (e.g., Bca, Cca), a dated reference to the harmonized standard, the ID number of the notified body/laboratory, and the intended product use. The cable itself must also be marked with a dated reference to the harmonized standard and its CPR class.

Best Practices for Fiber Optic Cable Project Implementation and Auditing

Successful project implementation and auditing require adherence to best practices that ensure compliance and optimal performance. Project managers must integrate regulatory compliance as an essential part of the planning process. This requires obtaining permits and inspections before any installation begins. They should conduct comprehensive site surveys to assess terrain, soil conditions, existing utilities, and environmental factors. Regulatory compliance research is also crucial to investigate local building codes, right-of-way requirements, environmental regulations, and safety standards, including specific requirements for cable burial depths and aerial clearances. Considering cultural and logistical aspects, such as local work practices, permit acquisition processes, and community engagement requirements, helps ensure smooth execution. Identifying potential hazards through risk assessment, including natural disasters, political instability, or infrastructure limitations, mitigates risks.

During installation, adhere to national and local building codes and telecommunications standards to ensure seamless integration with existing infrastructure. Implement structured cabling methodologies for organizing fiber pathways to reduce interference and simplify troubleshooting. Prioritize minimizing obstacles and potential environmental hazards when selecting a route to ensure efficient installation. Consider future expansion and the integration of existing telecommunications infrastructures during cable route planning.

Quality assurance procedures specific to installations are vital. Ensure proper disposal of glass shards using specialized containers to prevent injuries. Maintain a well-organized work area to enhance safety and reduce mishandling of cables and tools. Establish a proactive maintenance schedule to contribute to the longevity and performance of systems.

Rigorous testing and certification post-installation are mandatory. This includes OTDR analysis, insertion loss testing, and continuity checks to verify performance and adherence to design specifications. Conduct pre-installation testing to verify cable integrity and optical performance using OTDR and power meter testing. Monitor installation continuously for pulling tension, bend radius, and environmental conditions. Perform comprehensive post-installation testing, including insertion loss, return loss, and OTDR characterization. Maintain documentation records according to international standards (IEC 60794, ITU-T recommendations) and local regulatory requirements.

Future Trends and Evolving Regulations for Fiber Optic Cables

Upcoming Changes in EU Standards for Fiber Optic Cables

The European Union consistently updates its regulatory framework. These updates ensure products meet evolving safety, environmental, and performance benchmarks. Future changes in EU standards for fiber optic cables will likely focus on enhanced fire safety, stricter material restrictions, and improved circular economy principles. Regulators may introduce new classifications or expand the scope of existing directives like CPR and RoHS. Project managers must stay informed about these developments. Proactive monitoring helps ensure continued compliance and avoids potential disruptions to pan-European projects.

Impact of Green Initiatives and Sustainability on Fiber Optic Cable Compliance

Green initiatives and sustainability goals increasingly shape the fiber optic cable industry. The EU’s commitment to a circular economy and net-zero emissions drives demand for environmentally friendly products. Manufacturers now prioritize sustainable practices throughout the cable lifecycle, from raw material sourcing to end-of-life management. This focus translates into new compliance requirements and market expectations.

Companies actively pursue certifications to demonstrate their commitment:

- Superior Essex has achieved the Living Product Challenge (LPC) certification for its cables.

- This certification highlights a commitment to product transparency and sustainable manufacturing.

- LPC certification allows Superior Essex to engage more with the green building community.

- The company sought LPC certification to validate its leading sustainability practices.

- Prysmian Group introduced an ‘ECO CABLE’ certification for its telecom cables, including fiber optics.

- This certification uses a six-point matrix-based scoring system.

- Criteria include CO2 calculations from manufacturing, cable density, and avoidance of hazardous materials.

- The ECO CABLE initiative strengthens Prysmian’s sustainability strategy.

- It provides transparent information on the ‘greenness’ of cables.

- Cables passing a data-driven threshold receive ECO CABLE certification.

- Approximately 30% of Prysmian Group’s optical telecom cables are currently ECO CABLE compliant.

- The program will expand to other regions, addressing increasing green expectations.

These initiatives show a clear industry shift towards greater environmental responsibility. They influence product design, material selection, and manufacturing processes.

Adhering to EU standards is paramount for successful pan-European fiber optic cable projects. Proactive compliance ensures project success, enhances safety, and effectively avoids penalties. Selecting compliant fiber optic cables remains a fundamental requirement for any EU-based deployment. This approach safeguards investments and promotes reliable network infrastructure.

FAQ

What is the main goal of the Construction Products Regulation (CPR) for fiber optic cables?

The CPR ensures fire safety for fiber optic cables in buildings. It mandates declaration of fire performance and CE marking. This regulation helps limit flame spread and smoke production.

Why is the RoHS Directive important for fiber optic cable materials?

RoHS restricts hazardous substances like lead and mercury in electronic products. This protects human health and the environment. Manufacturers must ensure their cables do not exceed specific concentration limits.

What does the CE marking on fiber optic cables indicate?

The CE marking shows the cable meets EU health, safety, and environmental requirements. It signifies compliance with directives like CPR. This mark allows free circulation within EU member states.

Post time: Jan-19-2026