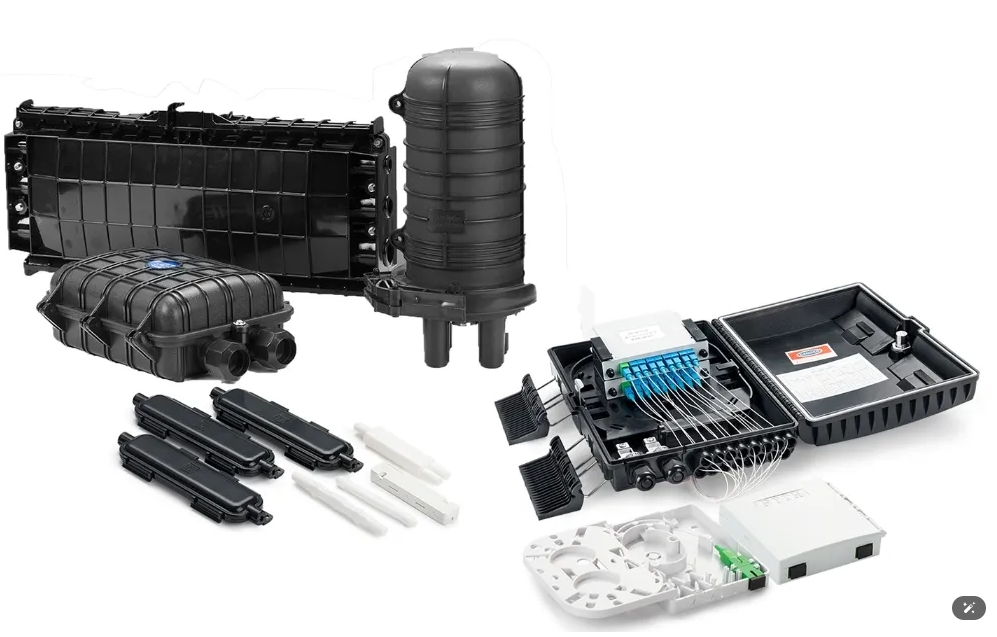

Dustproof fiber optic closures safeguard delicate fiber optic connections from environmental contaminants. These enclosures, including options like the 4 in 4 Out Fiber Optic Closure and High Density Fiber Optic Closure, prevent dust, moisture, and other particles from disrupting signal transmission. Proper maintenance ensures the longevity of these closures, whether used as underground fiber optic closures or Horizontal Fiber Optic Splice Closures, while maintaining optimal network performance.

Key Takeaways

- Check dustproof fiber optic closures often to find damage early. Look for cracks, worn seals, or tiny holes to keep them working well.

- Clean closures with special tools like lint-free wipes and rubbing alcohol. Do not use household cleaners that might leave harmful residue.

- Arrange and secure cables inside closures to avoid harm. Use cable ties and labels to make maintenance easier.

Preparation and Inspection of Dustproof Fiber Optic Closures

Tools and materials needed for maintenance

Proper maintenance of a dustproof fiber optic closure requires the right tools and materials to ensure efficiency and safety. Maintenance personnel should have access to:

- Safety tools such as gloves and goggles to protect against potential hazards.

- Role-specific tools, including fiber optic strippers and cleavers, designed for precise tasks.

- Advanced diagnostic tools like non-contact voltage detectors to identify issues without direct contact.

- Power tools that enhance productivity by reducing manual effort.

Using these tools ensures that maintenance tasks are performed accurately and efficiently, minimizing the risk of damage to the closures or the fiber optic cables inside.

Inspecting closures for damage or wear

Regular inspections are critical for identifying potential issues in dustproof fiber optic closures. Technicians should look for:

- Cracks or physical damage on the closure’s surface.

- Signs of wear on seals, which could compromise the dustproof environment.

- Evidence of porosity or voids, which can be estimated using attenuation measurements.

Quantitative methods, such as calculating the probability of failure (PoF), help prioritize maintenance efforts. For example, a PoF of less than 0.0001 indicates a highly reliable closure, with minimal risk of failure over time.

Preparing a clean, dust-free work environment

A clean workspace is essential for maintaining the integrity of a dustproof fiber optic closure. Follow these guidelines to create an optimal environment:

- Inspect dust collection systems regularly for wear or damage.

- Replace filters according to a scheduled maintenance plan.

- Sweep and vacuum the area to minimize dust accumulation.

- Train personnel on proper cleaning and safety procedures.

- Maintain detailed records of cleaning and maintenance activities.

These practices ensure that the workspace remains free of contaminants, reducing the risk of dust entering the closures during maintenance.

Cleaning and Sealing Dustproof Fiber Optic Closures

Proper cleaning tools and techniques

Maintaining the cleanliness of a dustproof fiber optic closure requires the use of specialized tools and techniques. Technicians should prioritize tools that are designed specifically for fiber optic maintenance to avoid damage. Essential cleaning tools include:

- Lint-free wipes: Prevents fibers or particles from contaminating the closure.

- Isopropyl alcohol (IPA): Removes grease and grime effectively.

- Compressed air cans: Blows away loose dust without physical contact.

- Fiber optic cleaning pens: Cleans connectors with precision.

Technicians should follow a systematic cleaning process. Begin by inspecting the closure for visible contaminants. Use lint-free wipes dampened with IPA to clean surfaces gently. Avoid excessive pressure to prevent scratches. For hard-to-reach areas, compressed air provides an effective solution. Always ensure tools are clean before use to maintain the integrity of the closure.

Tip: Replace cleaning tools regularly to avoid reintroducing contaminants during maintenance.

Removing dust and debris effectively

Dust and debris can compromise the performance of a dustproof fiber optic closure. Effective removal involves a combination of manual and automated methods. Start by opening the closure carefully to avoid disturbing internal components. Use a soft-bristled brush to dislodge stubborn particles from surfaces. Follow this with compressed air to remove loosened debris.

For internal components, such as fiber optic connectors, use a cleaning pen or cassette cleaner. These tools ensure thorough cleaning without damaging delicate parts. After cleaning, inspect the closure under a magnifying glass or fiber inspection scope to confirm the absence of contaminants.

Note: Avoid using household cleaning products, as they may leave residues that attract more dust over time.

Inspecting and replacing seals for a dustproof environment

Seals play a critical role in maintaining the dustproof environment of a fiber optic closure. Over time, seals may degrade due to environmental factors or wear and tear. Regular inspection ensures that seals remain effective. Look for signs of cracking, warping, or discoloration. If any damage is detected, replace the seal immediately to prevent dust ingress.

When replacing seals, select materials compatible with the specific closure model. Silicone or rubber seals are commonly used due to their durability and flexibility. Apply a thin layer of silicone grease to the new seal before installation. This enhances the seal’s effectiveness and prolongs its lifespan. After installation, test the closure by simulating environmental conditions, such as exposure to dust or moisture, to verify its performance.

Pro Tip: Store spare seals in a cool, dry place to prevent premature degradation.

Cable Management and Functionality Testing

Organizing and securing cables within the closure

Proper cable management within a dustproof fiber optic closure is essential for maintaining network reliability and simplifying future maintenance. Technicians should ensure that cables are neatly arranged and securely fastened to prevent tangling or damage. Using cable ties, clips, or Velcro straps can help organize cables effectively without causing strain on the fibers.

Organized cable setups offer several advantages. They minimize signal interference, reduce the risk of hardware failures, and enhance overall system performance. Industries such as IT, telecommunications, and healthcare rely on efficient cable management to maintain reliable communication networks. Additionally, organized cables optimize airflow within closures, which is critical for preventing overheating and ensuring long-term functionality.

Tip: Label cables clearly to identify connections quickly during troubleshooting or upgrades.

Testing fiber optic connections for performance

After organizing the cables, technicians must test the fiber optic connections to verify their performance. This step ensures that the network operates at optimal efficiency and identifies any potential issues before reassembling the closure. Use tools such as an optical time-domain reflectometer (OTDR) or a power meter to measure signal strength and detect faults.

Testing is particularly important in environments where advanced technologies like 5G and IoT are prevalent. These technologies increase the volume of data transmitted, making it crucial to ensure that connections are free from interference or degradation. Regular performance testing also simplifies maintenance and reduces downtime, contributing to a more reliable network.

Note: Always clean fiber optic connectors before testing to avoid inaccurate results caused by dust or debris.

Addressing issues identified during testing

If testing reveals any issues, technicians should address them promptly to prevent network disruptions. Common problems include signal loss, connector misalignment, or damaged fibers. Begin by inspecting the affected components to determine the root cause. Replace damaged connectors or cables as needed, and ensure that all connections are properly aligned.

For more complex issues, such as excessive signal attenuation, consider consulting with a specialist or using advanced diagnostic tools. Addressing problems during the maintenance process reduces the likelihood of future failures and extends the lifespan of the dustproof fiber optic closure. This proactive approach ensures that the network remains reliable and capable of handling high data volumes.

Pro Tip: Document all identified issues and the steps taken to resolve them. This record will be invaluable for future maintenance and troubleshooting.

Final Assembly and Storage of Dustproof Fiber Optic Closures

Reassembling closures securely

Reassembling a dustproof fiber optic closure requires precision to maintain its protective environment. Technicians should follow a systematic approach to ensure secure assembly:

- Inspect all seals for integrity and proper seating. Replace any damaged or worn seals.

- If moisture is present, dry the interior thoroughly before proceeding.

- Position seals and gaskets correctly to prevent gaps that could allow contaminants to enter.

- Reassemble the closure according to the manufacturer’s guidelines, ensuring all components are aligned and fastened securely.

Additionally, cables with metallic shielding or strength members should be properly grounded and bonded. Fibers and splices must be arranged carefully in splice trays to avoid stress or pinching. These practices ensure the closure remains dustproof and functional over time.

Storing closures in optimal conditions

Proper storage extends the lifespan of fiber optic closures. Closures should be stored in a clean, dry environment away from direct sunlight and extreme temperatures. Use protective covers or cases to shield them from dust and physical damage. Organize closures systematically to facilitate easy access during future maintenance or deployment.

Maintaining a controlled storage environment minimizes the risk of material degradation, ensuring the closures remain ready for use when needed.

Documenting maintenance activities for future reference

Accurate documentation is essential for effective maintenance and troubleshooting. Technicians should record all activities, including visual inspections, cable lengths, splice points, and any issues identified. Tools like an Optical Time-Domain Reflectometer (OTDR) can provide detailed diagnostic data, which should also be logged.

Maintaining a restoration plan with up-to-date documentation and contact lists ensures quick response times during repairs. Comprehensive records not only streamline future maintenance but also enhance the reliability of the network.

Tip: Keep documentation organized and accessible to all relevant personnel for seamless operations.

Maintaining dustproof fiber optic closures involves preparation, cleaning, cable management, and secure reassembly. Regular maintenance ensures long-term network reliability and prevents costly disruptions. Dowell’s high-density fiber optic solutions offer unmatched performance and adaptability. Clients have reported a 30% reduction in network expenses and improved connectivity, showcasing Dowell’s reliability for modern infrastructure needs.

FAQ

What is the recommended frequency for maintaining dustproof fiber optic closures?

Maintenance should occur every 6-12 months, depending on environmental conditions. High-dust or moisture-prone areas may require more frequent inspections and cleaning.

Can household cleaning products be used for fiber optic closures?

No, household cleaning products may leave residues that attract dust. Use specialized tools like lint-free wipes and isopropyl alcohol for effective and safe cleaning.

Tip: Always follow the manufacturer’s guidelines for maintenance to ensure optimal performance.

How can technicians ensure proper cable management within closures?

Technicians should use cable ties, clips, or Velcro straps to organize cables. Proper labeling simplifies troubleshooting and prevents damage during future maintenance.

Emoji Reminder:

Post time: Apr-14-2025