Fiber optic connectors serve as critical components in modern communication systems. These devices connect optical fibers, enabling seamless data transmission with exceptional speed and reliability. Their significance grows as the global fiber optics market expands. For instance:

- The market size is projected to reach $11.36 billion by 2030, reflecting steady growth.

- The fiber optic cable market is estimated to hit $20.89 billion by 2030, with a CAGR of 8.46%.

Research highlights the importance of precision in fiber optic connectors. Poorly manufactured connectors can cause network disruptions due to high insertion loss or surface imperfections. Eliminating such defects ensures consistent performance and minimizes failures.

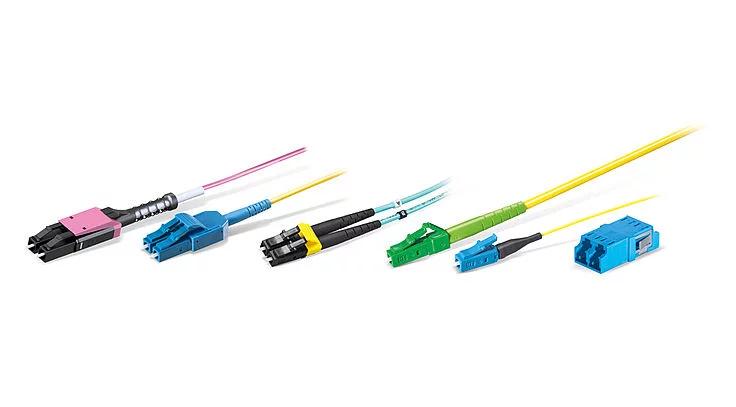

From the lc fiber optic connector to the sc fiber optic connector, each type plays a unique role in diverse applications. The st fiber optic connector, often used in networking, and the apc fiber optic connector, known for reducing signal loss, exemplify the versatility of these components.

Key Takeaways

- Fiber optic connectors help send data quickly and reliably. They reduce signal loss and keep communication systems working well.

- Picking the right connector depends on the cable, use, and environment. These factors affect how well it works.

- Good connectors like SC and LC are easy to install and fix. They are great for telecom and data centers.

What Are Fiber Optic Connectors?

Definition and Purpose

Fiber optic connectors are precision-engineered devices designed to join optical fibers, ensuring efficient light transmission. They enable seamless communication by aligning the fiber cores to minimize signal loss. Industry standards, such as IEC 61753-1, define these connectors based on performance metrics like insertion loss and return loss. For instance, insertion loss is categorized into grades A to D for single-mode fibers and grade M for multimode fibers. These standards ensure that connectors meet stringent requirements for reliability and performance. Additionally, Telcordia GR-3120 specifies criteria for hardened fiber optic connectors (HFOCs), which are built to endure harsh outdoor environments.

How Fiber Optic Connectors Work

Fiber optic connectors function by precisely aligning two fiber ends to allow light to pass through with minimal loss. The connector’s ferrule, typically made of ceramic or metal, holds the fiber in place. When connected, the ferrules of two fibers align, creating a continuous optical path. This alignment reduces insertion loss and ensures efficient data transmission. High-quality connectors also feature mechanisms to reduce return loss, which occurs when light reflects back into the fiber. These features make fiber optic connectors essential for maintaining signal integrity in communication systems.

Benefits of Using Fiber Optic Connectors

Fiber optic connectors offer several advantages. They simplify the installation and maintenance of fiber optic networks by providing a reliable method for connecting and disconnecting fibers. Their design ensures low insertion loss and high return loss, which are critical for maintaining signal quality. Additionally, they support high-speed data transmission over long distances, making them ideal for applications in telecommunications, data centers, and industrial environments. Their versatility and performance contribute to the growing adoption of fiber optic technology across various industries.

Common Types of Fiber Optic Connectors

SC (Subscriber Connector)

The SC connector, also known as the Subscriber Connector, is one of the most widely used fiber optic connectors. Its simple push-pull mechanism ensures quick and secure connections, making it ideal for high-density applications. The SC connector features a 2.5mm ferrule, which provides excellent alignment and low insertion loss. Its durability and ease of use make it a preferred choice in telecommunications and data networks.

Tip: The SC connector is particularly effective in applications requiring frequent reconnections due to its robust design and reliable performance.

LC (Lucent Connector)

The LC connector, or Lucent Connector, is a compact and efficient solution for high-density environments. Its small size and push-pull latch design allow for easy handling and installation. The LC connector uses a 1.25mm ferrule, which ensures high precision and low insertion loss.

- Advantages of LC Connectors:

- Compact design supports high-density applications.

- Durable construction with over 500 mating cycles.

- Operates efficiently across a wide temperature range.

- Common Use Cases:

- Telecommunications: Facilitates high-speed data transfer in internet and cable services.

- Data Centers: Connects servers and storage devices efficiently.

- Computer Networks: Enables high-speed connections in LANs and WANs.

ST (Straight Tip Connector)

The ST connector, or Straight Tip Connector, is a bayonet-style connector commonly used in networking applications. Its design includes a 2.5mm ferrule and a twist-and-lock mechanism, ensuring secure connections. The ST connector is particularly popular in industrial and military settings due to its rugged construction.

Note: While the ST connector is less common in modern installations, it remains a reliable choice for legacy systems and environments requiring robust performance.

FC (Ferrule Connector)

The FC connector, or Ferrule Connector, is designed for applications requiring high stability and precision. Its screw-on mechanism enhances stability under high vibrations, reducing insertion loss and maintaining signal integrity.

- Key Features:

- Screw-on design ensures secure connections in sensitive environments.

- Variants like FC/PC and FC/APC offer low back reflection and good insertion loss.

- Angled polish in FC/APC significantly reduces back reflection, ideal for return loss-critical applications.

MPO (Multi-Fiber Push-On)

The MPO connector is a high-density solution capable of connecting multiple fibers simultaneously. It is widely used in data centers and high-speed networks.

| Application Area | Performance Metric | Comparison Result |

|---|---|---|

| Automotive Manufacturing | Production line reconfiguration speed | 30% faster with MPO compared to legacy cabling |

| Medical Imaging Equipment | Data handling capability | 20GB/sec image data with MPO for intra-device interconnects |

| Military Applications | First-mate success rates in desert environments | 98.6% success rate with MPO, outperforming legacy types |

MT-RJ (Mechanical Transfer Registered Jack)

The MT-RJ connector is a compact and cost-effective option for duplex fiber connections. Its design resembles an RJ-45 connector, making it easy to handle and install. The MT-RJ connector is commonly used in small form-factor devices and local area networks.

Tip: The MT-RJ connector’s compact design makes it an excellent choice for space-constrained environments.

Specialized Connectors (e.g., E2000, SMA)

Specialized connectors, such as the E2000 and SMA, cater to niche applications. The E2000 connector features a spring-loaded shutter that protects the ferrule from dust and damage, making it suitable for high-performance environments. The SMA connector, on the other hand, is often used in industrial and medical applications due to its robust design and compatibility with various fiber types.

Note: Specialized connectors are designed to meet specific requirements, offering unique features that enhance performance and reliability in demanding applications.

Advantages and Disadvantages of Each Fiber Optic Connector

SC: Pros and Cons

The SC connector offers reliability and ease of use, making it a popular choice for high-density applications. Its push-pull mechanism simplifies installation, while its robust design ensures durability. However, its larger size compared to newer connectors limits its use in space-constrained environments.

| Connector Type | Mating Cycles | Insertion Loss | Features |

|---|---|---|---|

| SC | 1000 | 0.25 – 0.5 dB | Reliable, Fast deployment, Field fit |

Tip: SC connectors excel in environments requiring frequent reconnections due to their sturdy construction.

LC: Pros and Cons

The LC connector stands out for its compact design and high performance. Its small ferrule size enables space savings of up to 50% compared to SC connectors, making it ideal for high-density telecom applications. With insertion losses as low as 0.1 dB and return losses of ≥26 dB, it ensures minimal signal degradation. However, its smaller size can make handling more challenging during installation.

- Advantages:

- Compact design supports high-density environments.

- Low insertion loss enhances signal quality.

- High return loss minimizes signal reflection.

- Drawbacks:

- Smaller size may complicate handling.

- Requires precision during installation to avoid performance issues.

ST: Pros and Cons

The ST connector remains a reliable option for legacy systems and industrial applications. Its bayonet-style design ensures secure connections, even in environments with vibrations. However, its bulkier design and slower installation process make it less suitable for modern high-density networks.

Note: ST connectors are best suited for applications where ruggedness outweighs the need for compactness.

FC: Pros and Cons

The FC connector provides excellent stability and precision, particularly in environments with high vibrations. Its screw-on mechanism ensures secure connections, reducing insertion loss. However, early versions faced reliability challenges, such as fiber movement under temperature changes.

- Pros:

- Quick installation reduces setup time.

- Eliminates the need for epoxy adhesives and polishing.

- Ideal for fiber-to-the-desktop applications.

- Cons:

- Pistoning issues may degrade performance.

- Early models struggled with market acceptance due to reliability concerns.

MPO: Pros and Cons

The MPO connector supports simultaneous connections for multiple fibers, making it indispensable in data centers and high-speed networks. Its high-density design reduces cabling complexity and improves deployment speed. However, its intricate design requires careful handling to avoid alignment issues.

| Feature | Advantage | Limitation |

|---|---|---|

| High Fiber Count | Supports up to 24 fibers | Alignment challenges during mating |

| Deployment Speed | Faster installation | Requires specialized tools |

MT-RJ: Pros and Cons

The MT-RJ connector combines compactness with cost-effectiveness, making it suitable for local area networks. Its RJ-45-like design simplifies handling, but its limited fiber count restricts its use in high-capacity applications.

Tip: MT-RJ connectors are ideal for small-scale deployments where space and budget are key considerations.

How to Choose the Right Fiber Optic Connector

Cable Type Considerations (Single-Mode vs. Multi-Mode)

Selecting the right fiber optic connector begins with understanding the cable type. Single-mode and multi-mode cables differ in their core size, transmission distance, and application. Single-mode cables, with their smaller core size, are ideal for long-distance communication and high-speed data transfer. Multi-mode cables, on the other hand, are better suited for short-distance applications like local area networks (LANs).

Key factors to consider include:

- Physical Contact Types: Single-mode connectors often use physical contact (PC) or angled physical contact (APC) to enhance connectivity and reduce reflectance. APC connectors, for instance, are highly effective in applications like CATV.

- Color Coding: Single-mode cables typically feature yellow or blue jackets, while multi-mode cables are orange, aqua, or bright green. Connector colors also vary, with beige for multi-mode, blue for UPC single-mode, and green for APC single-mode connectors.

- Fiber Count: Applications requiring simplex, duplex, or multi-fiber cables should guide the choice of connector style.

| Key Considerations | Description |

|---|---|

| Optical fiber type and length | Evaluate the type of fiber (single-mode or multi-mode) and its length for specific applications. |

| Cable jacket type | Choose the appropriate jacket type based on environmental conditions and installation requirements. |

| Connector style | Select the connector style that matches the fiber type and application needs. |

| Number of fibers/fiber count | Determine the required number of fibers based on the application, whether simplex, duplex, or multi-fiber cables are needed. |

Application-Specific Selection (e.g., Data Centers, Telecommunications)

The application environment plays a significant role in determining the appropriate fiber optic connector. Data centers, for example, demand high-density solutions like MPO connectors to manage multiple fibers efficiently. Telecommunications networks often rely on LC or SC connectors for their compact design and reliable performance.

Consider the following when selecting connectors for specific applications:

- Data Centers: High-speed networks benefit from MPO connectors, which support up to 24 fibers in a single connection. This reduces cabling complexity and accelerates deployment.

- Telecommunications: LC connectors are preferred for their low insertion loss and compact design, making them suitable for high-density installations.

- Industrial Environments: Rugged connectors like ST or FC are ideal for environments with high vibrations or harsh conditions.

Tip: Matching the connector type to the application’s performance requirements ensures optimal efficiency and reliability.

Environmental Factors (Indoor vs. Outdoor Use)

Environmental conditions significantly impact the choice of fiber optic connectors. Indoor installations typically prioritize compactness and ease of handling, while outdoor environments require connectors that can withstand harsh conditions.

For outdoor use, hardened fiber optic connectors (HFOCs) are essential. These connectors comply with standards like Telcordia GR-3120, ensuring durability against temperature fluctuations, moisture, and dust. Indoor environments, on the other hand, often utilize LC or SC connectors for their compact design and ease of installation.

Key considerations include:

- Temperature Range: Ensure the connector can operate efficiently within the expected temperature range.

- Moisture Resistance: Outdoor connectors should feature robust sealing to prevent water ingress.

- Dust Protection: Specialized connectors like E2000 include spring-loaded shutters to protect against dust and damage.

Compatibility with Existing Equipment

Ensuring compatibility with existing equipment is crucial when selecting a fiber optic connector. Tools like the CertiFiber Pro Optical Loss Test Set help verify compatibility by managing test results and generating professional reports. LinkWare PC consolidates these results into a single report, highlighting performance metrics and potential issues.

To ensure seamless integration:

- Use automated statistical reporting to identify performance trends and anomalies.

- Verify that the connector meets the technical requirements of the existing system.

- Consult compatibility reports to confirm that the selected connector aligns with the equipment’s specifications.

Note: Compatibility testing minimizes the risk of performance issues and ensures a smooth installation process.

Fiber optic connectors play a pivotal role in modern communication systems. Their immunity to electromagnetic interference ensures reliable data transmission, reducing signal degradation. Compared to copper cables, fiber optics offer superior bandwidth, faster speeds, and greater energy efficiency. Selecting the right connector type, tailored to application and environmental needs, maximizes performance. Dowell provides high-quality fiber optic connectors, supporting diverse industries with reliable solutions.

Tip: Consult industry experts to ensure compatibility and optimal performance for your communication infrastructure.

FAQ

What is the difference between single-mode and multi-mode fiber optic connectors?

Single-mode connectors transmit data over long distances using a small core. Multi-mode connectors work for short distances with a larger core for higher bandwidth.

How do I clean fiber optic connectors?

Use a lint-free wipe or specialized cleaning tool. Avoid touching the ferrule directly to prevent contamination and ensure optimal performance.

Can fiber optic connectors be reused?

Yes, most connectors support multiple mating cycles. However, inspect for wear or damage before reuse to maintain signal integrity.

Post time: May-02-2025