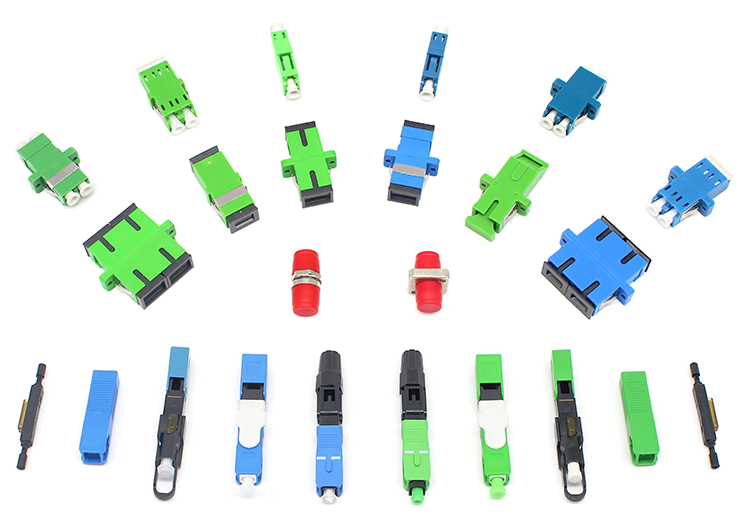

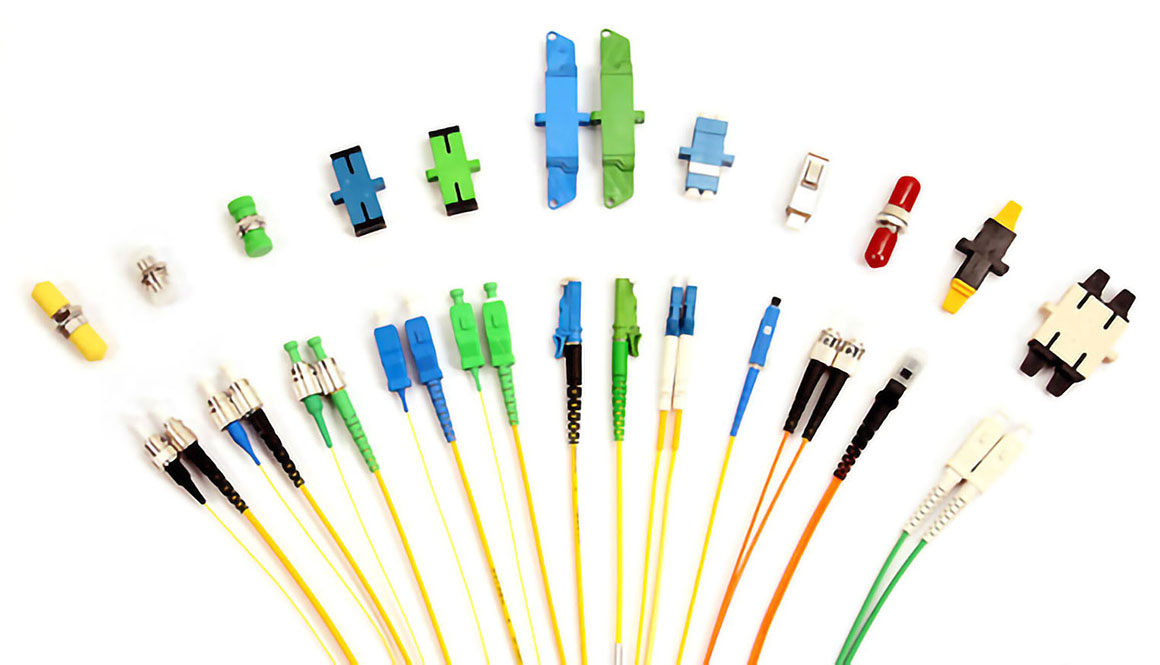

Fiber optic adapters play a critical role in modern communication systems, especially in extreme environmental conditions. Corrosion-resistant options ensure consistent performance by withstanding moisture, heat, and chemical exposure. Products like an SC APC adapter or SC Duplex adapter maintain signal integrity under these challenges. This durability minimizes maintenance and replacement needs, making them indispensable for long-term reliability. Additionally, solutions such as an SC UPC adapter or SC Simplex adapter align with the demands of industries that require robust and efficient connectivity. Choosing the right adapters guarantees uninterrupted operations in harsh climates.

Key Takeaways

- Rust-proof fiber optic adapters work well in tough environments. They need less fixing and replacing.

- These adapters keep signals strong by lowering signal loss and boosting return signals. This makes them great for busy systems.

- Spending on rust-proof adapters saves money over time. They cost more at first but lower running costs later.

- Fields like phone networks and airplanes use these adapters a lot. They help things run smoothly even in bad conditions.

- Picking the right adapters follows industry rules. This makes products better and keeps customers happy.

Challenges of Harsh Climates

Fiber optic systems often face significant challenges in environments characterized by extreme conditions. These challenges can compromise the performance and longevity of fiber optic adapters, making it essential for OEMs to prioritize solutions designed to withstand such adversities.

Types of Harsh Climates

Harsh climates can be classified into several categories based on mechanical stress factors. These classifications include varying levels of peak acceleration, displacement amplitude, and acceleration amplitude. The table below illustrates these classifications:

| Mechanical | M1 | M2 | M3 |

|---|---|---|---|

| Peak acceleration | 40 ms-2 | 100 ms-2 | 250 ms-2 |

| Displacement amplitude | 1.5 mm | 7.0 mm | 15.0 mm |

| Acceleration amplitude | 5 ms-2 | 20 ms-2 | 50 ms-2 |

Mechanical stress is just one aspect of harsh climates. Other factors include extreme temperatures, high humidity, and exposure to corrosive chemicals. These conditions are prevalent in industries such as oil and gas, telecommunications, and aerospace, where fiber optic systems must operate reliably despite environmental challenges.

Impact of Harsh Conditions on Fiber Optic Adapters

Harsh conditions can degrade fiber optic adapters in multiple ways. Corrosion caused by moisture and chemical exposure weakens the structural integrity of the adapters. High temperatures can lead to material deformation, while mechanical stress can cause physical damage. These issues result in signal loss, reduced performance, and frequent maintenance requirements.

Fiber optic adapters designed for harsh climates, such as corrosion-resistant models, mitigate these impacts. They maintain signal integrity by resisting environmental stressors, ensuring reliable connectivity even in extreme conditions. This durability reduces downtime and extends the lifespan of the system, making them a critical component for industries operating in challenging environments.

Benefits of Corrosion-Resistant Fiber Optic Adapters

Enhanced Durability and Longevity

Corrosion-resistant fiber optic adapters excel in durability, even under constant exposure to harsh environments. Their robust construction materials, such as aluminum, stainless steel, and glass-filled polymer, resist corrosion and maintain structural integrity over time. These materials ensure that the adapters can withstand extreme temperatures, high humidity, and exposure to chemicals without compromising performance.

| Material | Durability | Corrosion Resistance | Maintenance Needs |

|---|---|---|---|

| Aluminum | High | Excellent | Low |

| Stainless Steel | High | Excellent | Low |

| Glass-Filled Polymer | High | Excellent | Low |

The longevity of these adapters reduces the frequency of replacements, making them a cost-effective solution for industries operating in challenging conditions. Their ability to endure mechanical stress and environmental factors ensures uninterrupted operations, even in mission-critical applications.

Improved Signal Integrity and Performance

Corrosion-resistant fiber optic adapters maintain exceptional signal integrity, even in environments prone to electromagnetic interference or physical stress. These adapters minimize insertion loss and maximize return loss, ensuring high data fidelity over long distances.

| Parameters | Single-mode | Multimode |

|---|---|---|

| Typical Insertion Loss (dB) | 0.05 | 0.10 |

| Max Insertion Loss (dB) | 0.15 | 0.20 |

| Typical Return Loss (dB) | ≥55 | ≥25 |

| Operating Temperature (°C) | –40 to +75 | –40 to +75 |

| IP-Rating | IP68 | IP68 |

These performance metrics make them ideal for applications requiring high bandwidth and ultra-low latency, such as HD video streaming and real-time communication. By maintaining a high signal-to-noise ratio, these adapters ensure reliable connectivity, even in the most demanding environments.

Reduced Maintenance and Replacement Costs

The superior durability and performance of corrosion-resistant fiber optic adapters significantly reduce maintenance and replacement costs. Their resistance to environmental stressors minimizes the need for frequent inspections and repairs. This reliability translates into lower operational expenses and improved return on investment for businesses.

For industries like telecommunications, oil and gas, and aerospace, where downtime can result in substantial financial losses, these adapters provide a dependable solution. Their ability to maintain performance over extended periods ensures that systems remain operational with minimal intervention, enhancing overall efficiency.

Why OEMs Prioritize Corrosion-Resistant Fiber Optic Adapters

Meeting Industry Standards and Customer Expectations

OEMs prioritize corrosion-resistant fiber optic adapters to meet stringent industry standards and align with customer demands for reliable performance. Industries such as telecommunications, renewable energy, and industrial automation require components that can withstand harsh conditions while maintaining operational efficiency. For instance, offshore wind farms in Europe rely on fiber-optic networks for real-time turbine monitoring. These environments expose connectors to saltwater corrosion, making corrosion-resistant adapters indispensable.

The growing demand for robust connectivity solutions further underscores their importance. The industrial photonics market, projected to grow at an annual rate of 9.1% through 2030, highlights the increasing reliance on harsh-environment components. Notably, these solutions account for 28% of total component spending, reflecting their critical role in modern infrastructure.

Ensuring Reliability in Mission-Critical Applications

Corrosion-resistant fiber optic adapters ensure reliability in mission-critical applications where failure is not an option. Industries like aerospace and automotive manufacturing depend on these adapters to maintain uninterrupted operations. For example, Volkswagen’s Wolfsburg plant achieved a 40% reduction in signal loss during robotic welding by using IP67-rated fiber connectors. This improvement demonstrates how high-performance adapters enhance productivity and minimize downtime.

In addition, these adapters excel in environments with high electromagnetic interference or physical stress. Their ability to maintain signal integrity ensures seamless communication in applications such as 5G backhaul networks and data centers. By prioritizing reliability, OEMs deliver solutions that meet the rigorous demands of mission-critical operations.

Long-Term Cost Savings and ROI

Investing in corrosion-resistant fiber optic adapters offers significant long-term cost savings and return on investment (ROI). Although these adapters may have a higher initial cost, their durability and reduced maintenance requirements offset the expense over time. Hermaphroditic fiber optic connectors, for example, reduce labor time by up to 30% during field deployments. A major European telecom operator reported a 22% reduction in deployment costs for 5G backhaul networks after switching to these connectors.

Furthermore, data center operators experienced 30% faster cabinet installations using hermaphroditic MPO connectors. Despite their 40–60% higher purchase price, these connectors provided an 18% total cost reduction over three years. Enterprises absorb the initial price premium due to the operational benefits, making corrosion-resistant adapters a cost-effective choice for large-scale deployments.

By prioritizing these adapters, OEMs not only enhance system reliability but also deliver long-term economic advantages to their customers.

Corrosion-resistant fiber optic adapters play a vital role in maintaining reliable performance in extreme environments. Their ability to withstand harsh conditions ensures durability and reduces operational costs for industries. By prioritizing these adapters, OEMs meet stringent industry standards while delivering long-term value to their customers. This strategic investment benefits manufacturers by enhancing product reliability and supports end-users by minimizing maintenance needs.

Choosing corrosion-resistant solutions ensures uninterrupted operations and positions businesses for sustained success in challenging climates.

FAQ

What makes corrosion-resistant fiber optic adapters suitable for harsh climates?

Corrosion-resistant adapters use materials like stainless steel and glass-filled polymers to withstand extreme temperatures, moisture, and chemicals. These materials prevent degradation, ensuring long-term durability and reliable performance in challenging environments.

How do these adapters improve signal integrity?

Corrosion-resistant adapters minimize insertion loss and maximize return loss. This ensures high data fidelity, even in environments with electromagnetic interference or physical stress, making them ideal for mission-critical applications.

Are corrosion-resistant adapters cost-effective for OEMs?

Yes, their durability reduces maintenance and replacement costs. Although the initial investment may be higher, the long-term savings and improved system reliability provide a strong return on investment.

Which industries benefit most from corrosion-resistant fiber optic adapters?

Industries like telecommunications, aerospace, oil and gas, and renewable energy rely heavily on these adapters. Their ability to maintain performance in extreme conditions makes them indispensable for mission-critical operations.

How do these adapters align with industry standards?

Corrosion-resistant adapters meet stringent standards like IP68 ratings for water and dust resistance. This compliance ensures they perform reliably in demanding environments, meeting both regulatory requirements and customer expectations.

Tip: Choosing high-quality adapters, such as those offered by Dowell, ensures optimal performance and long-term reliability in harsh climates.

Post time: Apr-28-2025